Iridium makes meteorites heavier and makes human life easier. Iridium application

Chemistry

More than two centuries have passed since the first information about platinum, a white metal from South America, appeared. For a long time, people were sure that it was pure metal, just like gold. Only at the very beginning of the XIX century. Wollaston managed to isolate palladium and rhodium from native platinum, and in 1804 Tennant, studying the black precipitate remaining after the dissolution of native platinum in aqua regia, found two more elements in it. He called one of them osmium, and the second - iridium. Salts of this element were painted in different colors under different conditions. This property was the basis of the name: in Greek means "rainbow".

In 1841, the famous Russian chemist Professor Karl Karlovich Klaus began to study the so-called platinum residues, i.e., insoluble sediment remaining after processing raw platinum with aqua regia.

“At the very beginning of the work,” Klaus wrote, “I was surprised by the richness of my residue, because I extracted, besides 10% platinum, a considerable amount of iridium, rhodium, osmium, several palladium and a mixture of various metals of a special content ...”

Klaus informed the mountain authorities about the wealth of the remnants. The authorities became interested in the discovery of the Kazan scientist, which promised significant benefits. At that time, a coin was minted from platinum, and obtaining precious metal from the remains seemed very promising. A year later, the St. Petersburg Mint allocated Klaus a half-hour of leftovers. But they turned out to be poor platinum, and the scientist decided to conduct a study on them, "interesting for science."

“For two years,” Klaus wrote, “I was constantly engaged in this difficult, lengthy and even unhealthy research” and in 1845 I published the work “Chemical Investigation of the Remains of the Ural Platinum Ore and Ruthenium Metal”. This was the first systematic study of the properties of platinum analogues. It was also the first to describe the chemical properties of iridium.

Klaus noted that he was engaged in iridium more than other metals of the platinum group. In the chapter on iridium, he drew attention to the inaccuracies made by Berzelius in determining the basic constants of this element, and explained these inaccuracies by the fact that the venerable scientist worked with iridium containing an admixture of ruthenium, then unknown to chemists and discovered only in the course of a “chemical study of the residues Ural platinum ore and ruthenium metal. "

What is it, iridium?

The atomic mass of element No. 77 is 192.2. In the periodic table, it is between osmium and platinum. And in nature, it occurs mainly in the form of osmoid iridium - a frequent companion of native platinum. There is no native iridium in nature.

Iridium - Silver White MetalVery hard, heavy and durable. According to the company "International Nickel and Co.", this is the heaviest element: its density is 22.65 g / cm 3 and the density of its constant companion is osmium, the second most severe 22.61 g / cm 3. True, most researchers adhere to a different point of view: they believe that iridium is still a little lighter than osmium.

The natural property of iridium (aka Platinoid!) Is its high corrosion resistance. Acids do not act on it at normal or elevated temperatures. Even the famous aqua regia monolithic iridium "too tough". Only molten alkalis and sodium peroxide cause oxidation of element No. 77.

Iridium is resistant to halogens. He reacts with them with great difficulty and only at elevated temperatures. Chlorine forms four chlorides with iridium: IrCl, IrCl 2, IrCl 3 and 1 gCl 4. Iridium trichloride is most easily obtained from an iridium powder placed in a stream of chlorine at 600 ° C. The only halide compound in which iridium is hexavalent is IrF 6 fluoride. The finely ground iridium is oxidized at 1000 ° C and in a stream of oxygen, moreover, several compounds of different compositions can be obtained depending on the conditions.

Like all platinum group metals, iridium forms complex salts. Among them are salts with complex cations, for example, Cl 3 and salts with complex anions, for example, K 3 * ZN 2 0. As a complexing agent, iridium resembles its neighbors in the periodic table.

Pure iridium is obtained from native osmous iridium and from the remains of platinum ores (after platinum, osmium, palladium and ruthenium are extracted from them). We will not discuss the technology for producing iridium by sending the reader to the articles “Rhodium”, “Osmium” and “Platinum”.

Iridium is obtained in the form of a powder, which is then pressed into semi-finished products and melted, or the powder is melted in electric furnaces in an argon atmosphere. Pure hot iridium can be forged, but at ordinary temperature it is fragile and can not be processed.

Iridium in business

Pure iridium is used to make crucibles for laboratory purposes and mouthpieces for blowing refractory glass. Of course, iridium can also be used as a coating. However, there are difficulties. In the usual electrolytic way, iridium is hardly applied to another metal, and the coating is rather loose. Iridium complex hexachloride would be the best electrolyte, but it is unstable in aqueous solution, and even in this case, the quality of the coating leaves much to be desired.

A method has been developed for the preparation of iridium coatings by electrolysis from molten potassium and sodium cyanides at 600 ° C. In this case, a dense coating with a thickness of up to 0.08 mm is formed.

It is less time consuming to obtain iridium coatings by cladding. A thin layer of metal coating is laid on the base metal, and then this “sandwich” goes under a hot press. Thus, a tungsten and molybdenum wire with an iridium coating is obtained. A blank of molybdenum or tungsten is inserted into the iridium tube and forged in a hot state, and then dragged to the desired thickness at 500-600 ° C. This wire is used to make control grids in electronic tubes.

It is possible to apply iridium coatings on metals and ceramics chemically. To do this, get a solution of a complex salt of iridium, for example with phenol or some other organic substance. Such a solution is applied to the surface of the product, which is then heated to 350-400 ° C in a controlled atmosphere, i.e., in an atmosphere with a controlled redox potential. Under these conditions, the organics evaporate or burn out, and the layer of iridium remains on the product.

But coatings are not the main use of iridium. This metal improves the mechanical and physicochemical properties of other metals. It is usually used to increase their strength and hardness. The addition of 10% iridium to relatively soft platinum increases its hardness and tensile strength almost threefold. If the amount of iridium in the alloy is increased to 30%, the hardness of the alloy will not increase much, but the tensile strength will double even more - up to 99 kg / mm 2. Since such alloys have exceptional corrosion resistance, heat-resistant crucibles are made of them, which can withstand strong heating in aggressive environments. In such crucibles, in particular, crystals for laser technology are grown. Platinum-iridium alloys attract jewelers as well - jewelry made from these alloys is beautiful and hardly wears out. The platinum-iridium alloy is also used to make standards, sometimes a surgical instrument.

In the future, alloys of iridium with platinum may acquire special significance in the so-called low-current technology as an ideal material for contacts. Each time a normal copper contact closes and opens, a spark arises; as a result, the surface of the copper oxidizes quite quickly. In contactors for strong currents, for example for electric motors, this phenomenon is not very harmful to the work: from time to time the surface of the contacts is cleaned with sandpaper, and the contactor is ready for use again. But, when we deal with low-current equipment, for example, in communication technology, a thin layer of copper oxide very strongly affects the entire system, making it difficult for the current to pass through the contact. Namely, in these devices, the switching frequency is especially high - just remember the PBX (automatic telephone exchanges). It is here that the non-burning platinum-iridium contacts come to the rescue - they can work almost forever! It is only a pity that these alloys are very expensive and so far they are not enough.

Add not only to platinum. Small additions of element No. 77 to tungsten and molybdenum increase the strength of these metals at high temperature. The scanty addition of iridium to titanium (0.1%) sharply increases its already considerable resistance to the action of acids. The same applies to chrome. Thermocouples consisting of iridium and an alloy of iridium with rhodium (40% relatives) work reliably at high temperatures in an oxidizing atmosphere. Iridium alloy with osmium are soldered to fountain pen pens and compass needles.

Summarizing, we can say that metallic iridium is used because of its constancy. Like other metals of group VIII, iridium can be used in the chemical industry as a catalyst. Iridium-nickel catalysts are sometimes used to produce propylene from acetylene and methane. Iridium was part of the platinum catalysts for the reaction of the formation of nitrogen oxides (in the process of producing nitric acid) .. One of the iridium oxides, Ir0 2, was tried to be used in the porcelain industry as black paint. But this paint is too expensive ...

The reserves of iridium on Earth are small, its content in the earth's crust is estimated in millionths of a percent. The production of this element is also small - not more than a ton per year. Worldwide! In this regard, it is difficult to assume that over time dramatic changes will occur in the fate of iridium - it will forever remain a rare and expensive metal. But where it is used, it serves without fail, and in this unique reliability the guarantee that science and industry of the future will not do without iridium.

Iridium Watchman. In many chemical and metallurgical industries, for example in the blast furnace, it is very important to know the level of solid materials in the aggregates. Usually for such control bulky probes are used, suspended on special probe winches. C. In recent years, probes have been replaced by small-sized containers with an artificial radioactive isotope - iridium-192. The 1921 nuclei emit high-energy gamma rays; the half-life of the isotope is 74.4 days. Part of the gamma rays is absorbed by the charge, and radiation detectors record the attenuation of the flow. The latter is proportional to the distance that the rays travel in the charge. Iridium-192 is also successfully used to control welds; with its help, all undigested places and foreign inclusions are clearly recorded on film. Iridium-192 gamma flaw detectors are also used to control the quality of steel products and aluminum alloys.

MOSSBAUER EFFECT. In 1958, a young physicist from Germany, Rudolf Mössbauer, made a discovery that attracted the attention of all physicists in the world. The effect discovered by Mossbauer made it possible to measure very weak nuclear phenomena with amazing accuracy. Three years after the opening, in 1961, Mössbauer received the Nobel Prize for his work. This effect was first detected on the nuclei of the iridium-192 isotope.

HEART BEATS ACTIVE. One of the most interesting applications of platinum-iridium alloys in recent years is the manufacture of electrical stimulators of cardiac activity from them. Electrodes with platinum-iridium clamps are implanted in the heart of a patient with angina pectoris. The electrodes are connected to a receiver, which is also in the patient’s body. A generator with a ring antenna is located outside, for example, in a patient’s pocket. The ring antenna is mounted on the body opposite the receiver. When the patient feels that there is an attack of angina pectoris, he turns on the generator. The ring antenna receives pulses that are transmitted to the receiver, and from it to the platinum-iridium electrodes. The electrodes, transmitting impulses to the nerves, make the heart beat faster. Now in Russia, many ambulance stations are equipped with similar generators. In case of cardiac arrest, an incision is made of the clavicular vein, an electrode connected to the generator is inserted into it, the generator is turned on, and after a few minutes the heart starts working again.

ISOTOPES-STABLE AND UNSTABLE. In previous notes, quite a lot was said about the iris-192 radioisotope, which is used in numerous devices and even involved in an important scientific discovery. But, besides iridium-192, this element has 14 more radioactive isotopes with mass numbers from 182 to 198. The heaviest isotope at the same time is the shortest-lived, its half-life is less than a minute. The iridium-183 isotope is interesting only in that its half-life is exactly one hour. Iridium has only two stable isotopes. The heavier - iridium-193 in the natural mixture accounts for 62.7%. The proportion of light iridium-191, respectively, 37.3%.

USEFUL CHLORIDATES. Chloridates are complex chlorides of tetravalent iridium; their general formula is Me 2. Thanks to chloridates, it is possible in principle to confidently separate compounds of similar elements such as sodium and potassium. Sodium chloride is soluble in water, and potassium chloride is practically insoluble. But for such an operation, chloridates are too expensive, since the original iridium is expensive. This does not mean, however, that chloridates are generally useless. The ability of iridium to form these compounds is used to isolate element No. 77 from a mixture of platinum metals.

Pure iridium is used to make crucibles for laboratory purposes and mouthpieces for blowing refractory glass. You can, of course, be used as a coating. However, there are difficulties. With the usual electrolytic method, it is difficult to apply another metal, and the coating is rather loose. Iridium complex hexachloride would be the best electrolyte, but it is unstable in aqueous solution, and even in this case, the quality of the coating leaves much to be desired.

A method has been developed for producing iridium coatings by electrolysis from molten potassium and sodium cyanides at 600 ° C. In this case, a dense coating with a thickness of up to 0.08 mm is formed.

It is less time consuming to obtain iridium coatings by cladding. A thin layer of metal coating is laid on the base metal, and then this “sandwich” goes under the hot press. Thus, a tungsten and molybdenum wire with an iridium coating is obtained. A blank of molybdenum or tungsten is inserted into the iridium tube and forged in a hot state, and then dragged to the desired thickness at 500-600 ° C. This wire is used to make control grids in electronic tubes.

It is possible to apply iridium coatings on and ceramics chemically. To do this, receive the creation of a complex salt of iridium, for example with phenol or some other organic substance. Such a solution is applied to the surface of the product, which is then heated to 350-400 ° C in a controlled atmosphere, i.e. at atmosphere with controlled redox potential. Under these conditions, the organics evaporate or burn out, and the layer of iridium remains on the product.

But coatings are not the main use of iridium. This metal improves the mechanical and physicochemical properties of other metals. It is usually used to increase their strength and hardness. The addition of 10% iridium to relatively soft platinum increases its hardness and tensile strength almost threefold. If the amount of iridium in the alloy is increased to 30%, the hardness of the alloy will not increase much, but the tensile strength will increase by half - up to 99 kg / mm 2. Since they have exceptional corrosion resistance, heat-resistant crucibles are made of them, which can withstand strong heating in aggressive environments. In such crucibles, in particular, crystals for laser technology are grown. Platinum-iridium also attract jewelers - jewelry made of these alloys is beautiful and almost never wear out. Standards are also made of platinum-iridium alloy, sometimes a surgical instrument.

AT in the future, iridium with platinum may acquire special significance in the so-called low-current technology as an ideal material for contacts. Every time a short circuit occursand opening of an ordinary copper contact, a spark occurs; as a result, the surface of the copper oxidizes quite quickly.AT contactors for strong currents, for example for electric motors, this phenomenon is not very harmful to the work: from time to time the surface of the contacts is cleaned with sandpaper, and the contactor is ready for use again. But, when we deal with low-current equipment, for example, in communication technology, a thin layer of copper oxide very strongly affects the entire system, making it difficult for the current to pass through the contact. Namely, in these devices, the switching frequency is especially high - just remember the PBX (automatic telephone exchanges). It is here that the non-burning platinum-iridium contacts come to the rescue - theymay work almost forever! It’s only a pity thatthese alloys are very expensive and while they are not enough.

Add not only to platinum. Small additions of element No. 77 to tungsten and molybdenum increase the strength of these metals at high temperature. The scanty addition of iridium to titanium (0.1%) sharply increases its already considerable resistance to the action of acids. the same applies to chrome. Thermocouples consisting of iridium and an alloy of iridium with rhodium (40% rhodium) work reliably at high temperatures in an oxidizing atmosphere. Iridium alloy with osmium are soldered to fountain pen pens and compass needles.

Summarizing, we can say that metallic iridium is used mainly because of its constancy - the dimensions of metal products, its physical and chemical properties are constant, and, so to speak, are constant at the highest level.

Like other VIII groups, iridium can be used in the chemical industry as a catalyst. Iridium-nickel catalysts are sometimes used to produce propylene from acetylene and methane. Iridium was a part of platinum catalysts for the formation of nitrogen oxides (in the process of producing nitric acid). One of the iridium oxides, IrO 2, was tried to be used in the porcelain industry as black paint. But this paint is too expensive ...

The reserves of iridium on Earth are small, its content in the earth's crust is estimated in millionths of a percent. The production of this element is also small - not more than a ton per year. Worldwide!

In this regard, it is difficult to assume that over time dramatic changes will occur in the fate of iridium - it will forever remain a rare and expensive metal. But where it is used, it serves without fail, and in this unique reliability the guarantee that science and industry of the future will not do without iridium.

Iridium Watchman. In many chemical and metallurgical industries, for example indomain it is very important to know the levelsolid materials in aggregates.Usually for this control use bulky probes suspendedon special probe winches. AT in recent years, probes have begun to replacesmall containers with artificial radioactiveisotope - iridium -192. The 192 Ir nuclei emit gamma rays of high

energy the half-life of the isotope is 74.4 days, part of the gamma rays is absorbed by the charge, and radiation detectors record the attenuation of the flow. The latter is proportional to the distance,

which the rays pass in the charge. Iridium-192 is also successfully used to control welds; with its help, all undigested places and foreign inclusions are clearly recorded on film. Iridium-192 gamma flaw detectors are also used to control the quality of steel products and aluminum alloys.

MOSSBAUER EFFECT. In 1958, young physicist from germany rudolph

Mossbauer made a discovery that attracted the attention of all physicists in the world. The effect discovered by Mossbauer made it possible to measure very weak nuclear phenomena with amazing accuracy. Three years after the opening, in 1961, Mössbauer received the Nobel Prize for his work. This effect was first detected on the nuclei of the iridium-192 isotope.

Beats more active. One of the most interestingchanges platinum-iridium alloys in recent years - the manufacture of electrical stimulants of cardiac activity from them.AT Patients with angina pectoris are implanted with platino-iridium clamps. The electrodes are connected to a receiver, which is also in the patient’s body. A generator with a ring antenna is located outside, for example, in a patient’s pocket. The ring antenna is mounted on the body opposite the receiver. When the patient feels that there is an attack of angina pectoris, he turns on the generator. Pulses are transmitted to the ring antenna, which are transmitted to the receiver, and from it to platinum-iridium electrodes. The electrodes, transmitting impulses to the nerves, make them beat harder.

STABLE AND UNSTABLE. In previous notes, quite a lot was said about the iris-192 radioisotope, which is used in numerous devices and even involved in an important scientific discovery. But, besides iridium-192, this element also has 14 radioactive isotopes with mass numbers from 182 to 198. The heaviest isotope at the same time is the shortest-lived, its half-life is less than a minute. The iridium-183 isotope is interesting only in that its half-life is exactly one hour. Iridium has only two stable isotopes. Onshare heavier - iridium-193 in the natural mixture62,7%. The proportion of light iridium-191, respectively, 37.3%.

Iridium was discovered in 1804 by Tennan (simultaneously with osmium). Its name (Greek rainbow) indicates the multicolor of its compounds. In nature, it forms minerals from the osmoid iridium group: syrserkite (Os, Ir), ruthenic syrserkite and genera syrserkite, as an impurity that is part of copper-nickel sulfide ores.

Receiving:

Natural minerals or sludges of copper electrorefining are fused with barium peroxide BaO 2, dissolved in HCl, aqua regia is added, and after distillation of OsO 4, (NH 4) 2 is precipitated from the solution, which is calcined to Ir in a stream of hydrogen.

Physical properties:

Iridium is a silver-white, very hard and rather brittle metal in which individual crystals are distinguishable. At a temperature of red heat it is small, but it can be filed and polished. Density 22.65 g / cm 3, mp \u003d 2447 ° C.

Chemical properties:

Compact iridium is stable when heated in air to 2300 ° C, iridium powder, when heated in air, oxidizes to IrO 2 dioxide, interacts with halogens, sulfur, and phosphorus.

Neither ordinary acids nor aqua regia act on iridium. However, hydrochloric acid containing oxygen corrodes it when heated. Iridium powder is slowly oxidized by molten peroxides (BaO 2, Na 2 O 2).

In compounds, it exhibits oxidation states of +3, +4, less often others from +1 to +6.

At very low temperatures, iridium compounds are obtained, where it exhibits higher oxidation states (+7, +8, +9), for example: IrO 4 and cation +.

The most important connections:

Iridium (III) hydroxide Ir (OH) 3, more precisely hydrated iridium (III) oxide Ir 2 O 3 * nH 2 O, a green precipitate is obtained by precipitation from a solution of sodium chloroiridate (III) Na 3. Iridium (III) compounds are reducing agents; Ir (OH) 3 is oxidized by oxygen to Ir (OH) 4. Ir 2 O 3 when heated disproportionates to Ir and IrO 2.

Iridium (IV) oxide. IrO 2 is obtained as a blue-black powder by decomposition of hydroxide or by oxidation of iridium. Resistor material.

Iridium (IV) hydroxide Ir (OH) 4. The dark blue amorphous substance is insoluble in water, solutions of acids and alkalis, except for concentrated sulfuric acid. Obtained by alkaline hydrolysis of (NH 4) 2.

Halides. The product of the direct interaction of iridium with fluorine is iridium hexafluoride IrF 6. This compound is very active, it not only reacts with water according to the equation

IrF 6 + 5H 2 O \u003d Ir (OH) 4 + 6HF + 1 / 2O 2,

but even oxidizes chlorine, whereby IrF 4 and ClF are formed. Used for coating.

Iridium (III) and (IV) chloridescrystals are hydrolyzed by water. The formation of complex chlorides during interaction with alkali metal chlorides is characteristic: Na 3 - green crystals, Na 2 - dark red, soluble, potassium and ammonium hexachloroiridates (IV) - sparingly soluble.

Salts of iridium. In general, iridium forms few common salts. Salts of iridium (III) with complex cations are similar to the corresponding salts of chromium (III) and cobalt (III), are durable complex compounds X 3, X 3, X 2.

Iridium carbonyls: the yellow-green Ir 2 (CO) 8 is sublimated, and the bright yellow Ir 4 (CO) 12 decomposes upon heating. Used for coating.

Application:

For coating (electrical contacts, chemical equipment), the manufacture of crucibles. A component of superhard and wear-resistant alloys with osmium and ruthenium (supporting axes of precision instruments, pen nibs for fountain pens).

Sources: Iridium Wikipedia, the free encyclopedia. https://ru.wikipedia.org/wiki/Iridium

S.I. Venetsky On rare and scattered. Stories about metals.

Iridium metal precipitates after the dissolution of platinum in sulfuric acid. After the reaction, the metal turns black. However, its name translates as "rainbow". The fact is that iridium salts are a storehouse of colors. Compounds with chlorine are brown; with fluorine - yellow; with bromine - blue. So the element received the name of the Greek goddess Irida, and she, as you know, commanded the rainbow.

Discovered metal chameleon Smithson Tennat. The Englishman did this in the 1804th year. From the fact that iridium precipitate remains after the reaction of platinum with concentrated acid, it follows that the rainbow element is almost invincible. Only sodium peroxide and molten alkali dissolve it.

Unique not only iridium properties, and he himself is rare. Geologists suggest that in the bowels of the Earth its only one ten billionth share. One ounce, and this is only about 30 grams, costs more than a thousand dollars. The source of iridium is not only platinum, but also copper-nickel ores. True, the content of rare metal in them is negligible.

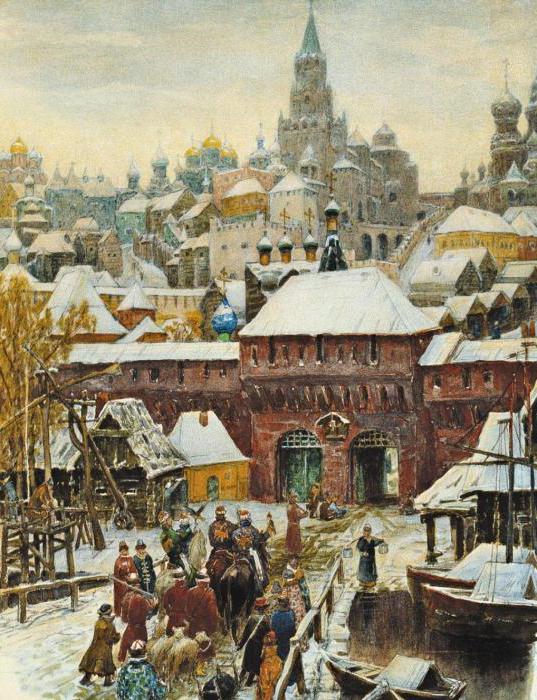

Scientists attribute such a low concentration of iridium in the earth's crust to its extraterrestrial origin. It is believed that iridium brought meteorites and asteroids that fell on the planet for the entire time of its existence. Otherwise, experts say, heavy metals (to which iridium belongs) should not be in the earth's crust at all. With the formation of the planet, all heavy elements settled in the core. It is under such pressure that no force can throw at least a gram of the center of the earth onto its surface. The conclusion, scientists note, suggests itself. Especially since the presence of iridium in meteorites - a fact recorded.

Scientists attribute such a low concentration of iridium in the earth's crust to its extraterrestrial origin. It is believed that iridium brought meteorites and asteroids that fell on the planet for the entire time of its existence. Otherwise, experts say, heavy metals (to which iridium belongs) should not be in the earth's crust at all. With the formation of the planet, all heavy elements settled in the core. It is under such pressure that no force can throw at least a gram of the center of the earth onto its surface. The conclusion, scientists note, suggests itself. Especially since the presence of iridium in meteorites - a fact recorded.

According to the layers of the earth’s crust, in which the concentration of rainbow metal is high, geologists even draw conclusions about the strength of the “cosmic attack” on the Earth in one or another period of its existence. Iridium space, but needed for earthly affairs. From it, for example, make molds for growing crystals. In such tanks, any stone can be obtained, because the element, as indicated, does not enter into 99% of chemical reactions. That is, the forms from iridium are completely “indifferent” to the solutions placed in them.

The production of equipment is not complete without an element. Electrical contacts are made from iridium alloy and platinum. By the way, fuel tanks for spaceships are also made of an alloy based on a rainbow element. In automobiles, iridium is used in spark plugs.

The production of equipment is not complete without an element. Electrical contacts are made from iridium alloy and platinum. By the way, fuel tanks for spaceships are also made of an alloy based on a rainbow element. In automobiles, iridium is used in spark plugs.

Rare metal electrodes are also used in medicine. Doctors have found that if electrodes are implanted in a person’s brain, they can be cured of a list of diseases. The main thing is to correctly calculate the frequency of the signal supplied to the elements. Parkinson's disease treats an electrical signal at 25 Hz. A greater frequency alleviates the symptoms of schizophrenia and epilepsy.

The phrase “ radioactive iridium". Isotopes of the element are used in the irradiation of patients with cancer in order to stop the proliferation of tissues. Most often, a rare metal is placed in an ampoule and implanted into the tumor’s “body”.

Ocular prostheses are made from iridium, metal is added to hearing aids. Iridium coatings save other metals from corrosion. Metal is not subject to it even at a temperature of 2 thousand degrees Celsius. But, it is necessary to apply a protective layer electrolytically. Otherwise, the protective layer will not stay on the base.

Ocular prostheses are made from iridium, metal is added to hearing aids. Iridium coatings save other metals from corrosion. Metal is not subject to it even at a temperature of 2 thousand degrees Celsius. But, it is necessary to apply a protective layer electrolytically. Otherwise, the protective layer will not stay on the base.

If you know that iridium is also used in fountain pens and ballpoint pens, it becomes clear why some copies of writing instruments cost so much. The price is added not only to well-known manufacturers, but also balls from a rare element at the ends of feathers or ink rods.

Some instruments for surgery are made from an alloy of iridium with platinum. They have no demolition, as well as jewelry, "born" of the tandem of platinum and rainbow metal. Element No. 77 (such is its position in the periodic table) is therefore added to platinum jewelry because without iridium it is too soft, does not hold its shape. A ring or earring made of pure platinum will collapse even when pressed lightly.

True, products that contain iridium are expensive. Not only because the bluish-silver metal has already been ranked as precious, but also because it melts at a temperature of several thousand degrees. I.e get an iridium alloy with something is not so simple. We need special and very expensive equipment. So it turns out that for a small iridium ring without any stones they ask for an average of about 3 thousand dollars.

Suppliers of metal No. 77 to the world market are: - Canada, Russia, South Africa. In the bowels of the last country, iridium, as well as platinum and gold deposits, is most. With total reserves of iridium of 15 thousand tons, 10 thousand of them are hiding in the lands of South Africa. So, in the 2009th year, the world production of rare metal fell immediately by 13%. This is because, due to internal problems, the element began to be mined less in the Republic of South Africa. There was a shortage of iridium, prices for it jumped. So, although South Africa and a developing country, other states cannot develop without it.

Among enterprises, the leader in the production of iridium was recognized by Lonmin. It puts on the market a third of the global volume of this metal. It remains, he hopes, that meteorites will continue to fall to the ground, so as not to harm people. Otherwise, they will be harmed by the depletion of reserves of not only rare, but also extremely necessary metal for humanity.