Technopolises and import development zones in Japan. Japanese model of technoparks

?

CONTENT

1. STATE DEPARTMENT OF STP IN JAPAN 3

2. TECHNOPOLIS

3. TREND OF SCIENTIFIC AND TECHNICAL DEVELOPMENT 4

SMALL BUSINESSES IN JAPAN 7

3.1. Objective conditions conducive to the participation of small and medium-sized enterprises in the NTP process 7

3.2. The main types of strategy for scientific and technological development of small business 10

3.3 Features of R&D 13

REFERENCES 16

1. STATE DEPARTMENT OF STP IN JAPAN

Japan is a country of economic success that has managed to become one of the world leaders in a historically short period of time. Its recent history began in the 70s of the 19th century, when Japan emerged from feudal isolation with a strong national consensus: to avoid the fate of a Western colony. Japan needed Western technology and institutional examples, and it was all imported and assimilated. Accelerated industrialization relied on domestic financial and human resources without direct financial assistance from Western countries.

Organizational structure of state management of science and technology policy in Japan.

The Ministry of Foreign Trade and Industry (MTPI) plays a key role in determining the strategy for the development of Japan's industry, developing industrial R&D and their implementation. Control over the implementation of specific directions of scientific and technical progress is carried out by the Department for Science and Technology. Also under the auspices of the MVTP is the Japan Industrial Technology Association, which deals with the export and import of licenses. There is a long-term program of scientific and technological development of the country; applied research and the purchase of licenses abroad are being stimulated. In the implementation of scientific and technological progress, reliance is placed on large corporations. The role of the Department of National Defense is not great.

Government spending on R&D increased to 3.5% of GDP, mainly on basic research and the generation of fundamentally new ideas. Government policy is aimed at transforming Japan from an importer of licenses to an exporter.

The displacement of foreign competitors from existing markets due to the cheapness and high quality of goods is replaced by an even more difficult task - to form new markets ourselves, while maintaining low prices and high quality of new goods.

Japan's long-term goal is to transform the country from an "importer" and "rationalizer" into a technology creator. The priority area is information systems, mechatronics, biotechnology, new materials.

In addition to traditional economic and administrative methods of influencing the development of export production and exports, such as preferential crediting and export insurance, partial exemption of exporters from paying taxes, direct subsidies, state comprehensive assistance to exporters, promoting their marketing activities, Japanese government agencies also widely use indirect methods. ...

These include the following:

? Targeted distribution of financial resources provided by private banks and their concentration in priority sectors

? Assisting enterprises to acquire in advanced foreign technology

? Control over scientific and technical exchange with foreign countries.

The Japanese model of the integration of science and production, scientific and technological progress presupposes the construction of completely new cities-technopolises, concentrating R&D and high-tech industrial production.

2. TECHNOPOLIS

TECHNOPOLIS is a program developed in the early 80s. Ministry of Foreign Trade and Industry (MTPI) of Japan, which has become one of the key elements of the country's regional development strategy in the context of the transition to a knowledge-based industrial structure, accelerating scientific and technological progress, softization and servicing of the economy.

This program of city building in the XXI century. provided for a balanced and organic combination of high-tech industry, science (universities, engineering universities, research institutes, laboratories) and living space (prosperous and spacious living areas), as well as the combination of the rich traditions of the regions with advanced industrial technology. New research and production townships were conceived in Japan as multipurpose and complex, which distinguishes them from similar territorial entities in the United States and Europe. So, Japanese technopolises include not only science parks and research centers, capital and new technologies, but also new residential areas, roads, communications and communications.

Technopolises are fundamentally different from the territorial-production complexes that were created in Japan itself in the 60s and 70s. Their novelty consisted primarily in the fact that the most advanced industries and technologies that were at the stage of development or flourishing, characterized by science intensity and a high share of added value, were chosen as the main lever for raising the economy of peripheral regions. The process of selecting these industries and industries, as well as the development and implementation of specific development plans for each technopolis, was in the competence of local self-government bodies.

Technopolises were to be created in different parts of the country (but outside of large urban agglomerations) and become strongholds for the development of peripheral regions. It is interesting that initially the MVTP did not plan a large number of technopolises, but the interest in them in the regions turned out to be so high that it was decided to expand the circle of program participants. To date, the number of technopolises has reached 26.

In 1990, the deadline for the completion of the first stage of work for 20 technopolises, which were approved before 1985, came, and the Department of the Environment and Industry Location of the MVTP decided to develop plans for the second stage of the development of technopolises and make adjustments to the overall strategy. At the same time, some results of the development of technopolis zones were summed up. As a basis, 4 main indicators were taken: shipments of industrial products, the volume of value added created in industry, the same per employee, the number of people employed in industry. The survey results were that the average annual growth rate in 1980 -1989. on all indicators significantly lagged behind the forecast.

However, this does not give grounds to conclude that the very idea of technopolises or its practical implementation is untenable. The forecast indicators themselves are indicative. The program for the construction of technopolises is not a directive plan, it only defines a general development strategy, and from the very beginning it was assumed that it would be flexibly adjusted. So, in the 80s. the rate of the yen rose sharply, and in these conditions the industry rushed not to the provinces, but abroad. As a result, the forecasted indicators of industrial development laid down earlier in the project turned out to be overestimated. In addition, the different degrees of preparedness of the prefectures for the implementation of the program, the presence or absence of large companies in a particular locality interested in participating in the project, as well as strong leaders capable of leading it, had an effect.

Practice shows that the most successful technopolises are those located in areas of high and medium economic development - the north of Kyushu, Chugoku, Hokuriku, Kanto, Tokai. At the same time, high-tech industries have become the leaders in the industrial development of these zones, which indicates qualitative changes in the sectoral structure of industry in technopolises. In almost all technopolises, elements of a new research, production and information infrastructure are laid, which is a necessary foundation for future development. And this is perhaps the greatest achievement of the first stage of the Technopolis program. For 10 years, research centers, technoparks, high-tech centers, high-level information systems have been built in technopolises, joint research of universities and industry in the field of high technologies has intensified. Interestingly, there has been a long-term trend towards a slowdown in the outflow of graduates of local universities from their native places, as technopolises have opened up prospects for them to apply their knowledge.

Considering these circumstances, the results of the first stage of the creation of technopolises are generally assessed in Japan optimistically. In any case, both the government and local authorities are determined to continue building a network of technopolises in the country. In 1991, MVTP adjusted the general line of development of technopolises. At the same time, it was emphasized that stimulating the placement of high-tech industry in the province remains the main topic of the program, but it is necessary to look for new ways to effectively combine industry, science and education. At a new stage in the life of technopolises, support for R&D should come to the fore, aimed at educating "creative" people and "creative" industries, strengthening the service sector of a production nature ("the brains of industry"), creating a pleasant living environment, opportunities for sports and others. types of outdoor activities. It is also envisaged to strengthen the aspect concerning the connection between individual technopolises.

According to the MVTP, in the field of industrial development in the zones of technopolises, the center of gravity should be shifted from attracting enterprises from outside to supporting local enterprises. Therefore, when drawing up plans for the second stage, the prefectures were recommended to create funds to support the technological development of local industry and its revitalization, to improve the “soft” infrastructure in order to bridge the gap in capital efficiency between the attracted and local enterprises. Local authorities responded with enthusiasm to new ideas and proposals of the MVTP. All 20 technopolises have developed new plans for further development, with which Japanese regions will enter the 21st century.

3.TENDENCY OF SCIENTIFIC AND TECHNICAL DEVELOPMENT OF SMALL BUSINESSES IN JAPAN

Scientific and technical potential is one of the most important resources for the management of small and medium-sized enterprises (SMEs), a decisive factor in maintaining their competitiveness in the domestic and foreign markets. Although, in terms of the level of development of technology and technology, SMEs differ greatly (along with firms where the production process passes the initial stage of mechanization, there are highly developed companies specializing in R&D in high-tech knowledge-intensive industries), a general trend during the post-war period was an increase in the role of small business in the scientific and technological development of the country.

3.1. Objective conditions conducive to the participation of small and medium-sized enterprises in the NTP process

A rapid rise in the technical and technological level of production began in Japan in the second half of the 50s, when it entered a period of high growth rates. The main direction during this period was the advanced development of a complex of branches of heavy industry, and the carriers of scientific and technological progress were large enterprises, which on a massive scale purchased the latest achievements in the field of technology and technology (both in the form of production equipment and in the form of patents and licenses).

The radical reconstruction of the production apparatus of large enterprises and the development by them of an ever wider range of new industries had a direct impact on the state of affairs in small business, since sooner or later they entailed changes in its technical base and necessitated a transition to the use of new types of raw materials and materials. This primarily affected subcontracting firms, on the technical level of which the competitiveness of large companies, rushing to world markets, increasingly depended. At the turn of the 60s and 70s, when labor shortages became apparent and workers' wages began to rise rapidly, a wave of technical renewal also affected some other categories of SMEs.

In general, although a part of SMEs during the period of high growth rates were able to significantly raise their technical level, switch to the use of new types of raw materials and materials and master the production of new types of products, the role of small business in the scientific and technological development of the country remained insignificant, since the absolute majority of SMEs continued focus on routine production methods and old technology.

With the accession of Japan in the mid-1970s, during a period of moderate growth, the situation for SMEs began to change rapidly. First, due to the increasing individualization of consumer demands and the increasing segmentation of production demand, which led to the reorientation of the economy from large-scale production to the production of various products in small batches, many new niches for small businesses have emerged on the market. Secondly, due to the fact that the leading role in scientific and technological progress has shifted to such areas as electronization, new materials, biotechnology, its "accessibility" for small firms has increased, since much less financial resources than before.

Since the second half of the 70s, SMEs began a radical restructuring of the production apparatus based on the transition from machine to mecatronic technology, which appeared on the wave of electronization as a result of equipping machines and equipment with microelectronic devices, which significantly increased their functional characteristics. The scale and intensity of this process is evidenced by the fact that for 1975 - 1990. the volume of investments in equipment for SMEs increased almost 3 times with an average annual growth rate of 12.6%.

This process also captured the first subcontracting enterprises, for which the introduction of mecatronic technology was almost the only way to meet the sharply increased requirements of the parent companies in terms of the level of production costs and product quality. By the beginning of the 1980s, 30-35% of SMEs in assembly machine-building industries, where 70-80% of firms were subcontracted with large companies, had some kind of mecatronic equipment in their equipment.

In the 80s, the equipping of production with microelectronic equipment and automation means, spreading along the production cycle to all new layers of subcontracting enterprises, began to capture other categories of SMEs, acquiring such a large-scale character that by the end of this 10th anniversary, the gap in the technical level between large and small businesses declined sharply.

1981 - 1990 the volume of investments in equipment per person employed in SMEs increased 2.5 times, and labor productivity (in terms of value added by processing) increased 1.6 times. By the end of the 1980s, about 70% of both SMEs and large firms had CNC machines, while in the mid-1980s only 3% of SMEs had them, versus 43% of large ones. The same applies to the degree of distribution of machine centers. In 1990, more than 40% of both SMEs and large companies had them, while in 1985 only 9% of small and 37 large firms.

At the same time, in such complex types of production equipment as automated production systems and computer-aided design systems, SMEs were noticeably inferior to large ones. Among SMEs, the share of firms that have such types of equipment is almost three times lower than among large ones (8 and 23%). However, this is largely due to the fact that, due to the small scale of production, their implementation in small firms is often economically ineffective.

During this period, there was a tendency towards a relative decrease in the role of external suppliers of innovations (primarily large

enterprises) to small businesses in favor of the small and medium-sized firms themselves. In the mid-80s, more than 10% of SMEs were already engaged in the development of new equipment and technology (in the mid-70s there were no more than 5% of such firms), and their share in the supply of new technology to small businesses increased to 28-30%.

The significant growth in the innovative potential of the Ministry of Railways is evidenced by the increase in their expenditures on R&D in 1977-1989. almost 2.5 times, an increase in the number of people employed in research and development by 1.2 times (up to 18% of total employment in the field of R&D), and the cost per employee - 2 times (up to about 30% of the level of large companies).

The trend towards narrowing the gap in the technical level of production between large and small businesses was accompanied by increased differentiation among SMEs. For subcontracting firms, this was due to the fact that orders from large companies were received by the most viable of them, whose technical level allowed them to meet the requirements imposed on them by large businesses in terms of the level of production costs and product quality. Being interested in strengthening such enterprises, the parent companies have significantly expanded the provision of various kinds of assistance to them, including in the form of technical assistance (supply of certain types of equipment, provision of new technology, consulting, financial assistance). As a result, the gap between this group and other subcontractors in terms of technical capabilities widened even further.

As for independent SMEs, among them (against the background of an increase in the general level of technology and production technology) there have also emerged firms that have managed to get ahead and become leaders in their respective fields. We are talking primarily about enterprises that manage medium-sized resources, which, as a result of the "crushing" of scientific and technological progress, were able to organize the development of an original technology and master the production of high-tech products on their own, as well as venture capital firms - small research-type enterprises that rely on the development of a unique technology and entering the market with unique products.

3.2. The main types of strategy for scientific and technological development of small business

The degree and forms of participation of SMEs in the STP process are determined by a combination of many factors, one of which, as shown by a study by Japanese specialists, is the size of enterprises in terms of the number of employees. Five groups of SMEs can be distinguished, each of which is characterized by a certain type of strategy for scientific and technological development.

? Enterprises employing up to three people, mainly of a family type, belonging to the category of subcontracting and engaged in the production of individual types of single products in small batches. Their main task is to meet customer requirements in terms of price, quality and delivery time.

products. The basis of production is often not machines, but tools, and competitiveness to a large extent

depends on the qualifications of the workers. Among this group, there are very few enterprises capable of developing their own technology.

or products, and the possibilities of their technical development largely depend on how interested in this

customers.

? Enterprises with 4 to 9 employees, most of which are also subcontractors, but in contrast to the first group, the basis of production here is standard products manufactured in relatively large batches on standard equipment. There is a fierce competition between enterprises for orders from parent companies, the core of which is -

cost price, quality and delivery time of products. The main focus is on more efficient use of equipment,

the use of special methods of work that allow you to bypass competitors at least slightly in cost and quality.

Opportunities for independent technical creativity, development of new products and new technology are limited here, therefore

the main direction of innovation is the production of products or the implementation of works that, even in

are somewhat different from what other companies can do. The carriers of new ideas are usually the owners themselves.

firms, and on their ability and intuition to

the capabilities of technical

development

? Enterprises with 10 to 29 employees, also mostly subcontractors, working on orders from the parent company, however, are characterized by a stronger desire to move away from the production of standard products and a focus on product output, which allows the company to occupy a special niche in the market. Improving the level of technology and technology is becoming a decisive factor in maintaining competitiveness, but the goal is not only and not so much to reduce costs, but to master the production of products that differ in their characteristics from what competitors can offer. The technical level of enterprises is quite high, while the importance of the personal qualities of managers is relatively decreasing, and the role of the organization (personnel training, labor organization, etc.) is growing. In the competition for orders from the parent company, the focus is not on methods of work or types of tools and equipment that are slightly different from other companies, but on the use of a set of obvious distinctive features of a given enterprise, which together form its special appearance and form the basis of its viability.

? Enterprises with the number of employees from 30 to 49 people are represented both by subcontractors of the parent companies that produce certain types of parts and assemblies or fulfill orders for carrying out certain types of work, and independent firms that produce the final product and deal with its direct consumers.

Subcontracting enterprises of this group, as a rule, are located close to the top of the pyramid - the parent company, and often form a single production mechanism with it. Their technical level is quite high, because under the pressure of the strict requirements of the parent companies in relation to product quality and the level of costs, they are forced to constantly improve the technique and production technology. The parent firms often provide technical assistance to these enterprises, from supplying equipment to joint R&D. As a result, among the subcontractors, a lot of specialized enterprises were formed that were able to develop their own original technology, which allowed them to significantly expand the scale of production and switch to servicing several customers at once.

Independent firms are characterized by a focus on the production of new products, both through the improvement of existing technologies and the development of new ones. The main task of managers is to determine the moment when the possibilities of the first path, which does not require significant investment of capital and time, are exhausted and in order to preserve the viability of the enterprise, it is necessary to move to the second path, which is associated with large financial and time costs.

Due to the size of enterprises, the management style focused on the individual capabilities of the superman manager encounters natural limitations, and the task of effectively using the capabilities of the entire organization comes to the fore (rational use of equipment, staff development, improvement of management, etc.).

? Enterprises with more than 50 employees, both subcontracted and independent (which prevail here), have a pronounced focus on the development and production of qualitatively new products, but not by improving the existing technology (which is characteristic of the previous group), but by creating a new one. With a high innovative potential, several types of market strategies can be distinguished, while their choice depends on the amount of financial resources of the enterprise, the ability to collect and process information, organize marketing research, etc.

Thus, among the enterprises of this group there are relatively small firms specializing only in R&D and the sale of technologies in the absence of production as such. Among enterprises with up to 100 employees, firms prevail, which, along with R&D, organize the production process, but their resources are usually insufficient for its establishment and marketing of products, so they turn to external channels. For firms with more than 100 employees, due to broader financial opportunities, it becomes typical to organize a full cycle - R&D, production, sales of products, including various types of after-sales services. Common to all enterprises in this group is an even greater decrease in the role of the head of the firm or top managers in scientific and technological development, with a significant increase in the value of the creative potential of the entire team.

Thus, as a result of the "fragmentation" of R&D, as well as individualization and segmentation of demand in the 70s and 80s, objective conditions arose for participation in the process of scientific and technological development of SMEs of different sizes and categories. Since the concept of STP includes various types of activities (scientific research, development of new products and technologies, introduction of new production methods, development of new types of resources, restructuring of organizational structures), the participation of SMEs in this process takes place in different forms - from connecting to certain types of innovative activities to active participation in all its types.

3.3 Features of R&D

The depressive state of the Japanese economy and the 90s and the action of a number of other factors (the influx of goods from Asian countries, the reorientation of large companies to place orders abroad, the closure of a number of production facilities, etc.) significantly complicated the situation for SMEs. In this situation, almost the main condition for survival for many of them is the development of new products, an increase in the level of technology and technology based on the development of R&D.

On the whole, SMEs managed to maintain their positions in this area and prevent an increase in the gap with large companies.

Thus, at the end of the 90s, expenditures on R&D per employee amounted to 29% of the level of large companies for SMEs (at the end of the 80s - 30%). Small businesses accounted for 6.2% of the total expenditures of the private sector on R&D (at the end of the 1980s - 6%) and 19% of the total number of people employed in this area (at the end of the 1980s - 18%).

The number of R&D SMEs is constantly growing. By the mid-90s, their share in the total number of SMEs rose to 22% against about 10% in the mid-80s. In the coming years, according to the SME Department, it could reach 38%.

The organization, content, direction and other characteristics of R&D in SMEs differ significantly from large companies.

? In terms of the content of R&D, there is a kind of division of labor between large companies and MSL: the former are mainly engaged in fundamental research, development of new products and technologies, complex technical research, improvement of production methods, and the latter, mainly in applied research, development of certain types of new products, improvement of existing ones. products and production methods.

Among large companies, almost 3/4 are engaged in fundamental research, among SMEs - only 1/5. The overwhelming majority of SMEs are focused on improving the consumer properties and improving the quality of existing products, as well as improving the equipment and technologies used.

? The time to complete work on a specific topic and the cost of carrying it out for SMEs is much less than for large ones. This is connected both with the specifics of the subject matter and with the desire of SMEs to recoup the investment as soon as possible and enter the market with a new product.

Thus, studies requiring less than one goal account for 2/3 of topics for SMEs and 1/3 for large ones, and for studies that take more than 5 years - 3 and 11%, respectively. Projects worth less than 5 million yen for SMEs account for 58% of the total, and for large ones - only 16%. For openings worth more than 100 million yen, the opposite picture is observed (9% and 37%, respectively).

? From the point of view of the organization of R&D, one can note the predominance of permanent scientific divisions in large companies - almost 90% of firms have them here, while among SMEs - only 40%. Moreover, this indicator varies significantly depending on

focus of R&D. So, among SMEs where R&D is focused on improving the consumer properties of existing products

or reducing costs and rationalizing production, the proportion of firms that have specialized scientific departments in their structures

development, is 31 and 13%, respectively. As for SMEs, where R&D is aimed at developing new products, the share of those with specialized scientific departments increases to 57%.

In addition, while in large firms research directions and project topics are determined by specialists (in conjunction with the company's development strategy), and their funding is carried out in accordance with an annual expenditure plan, then in SMEs R&D topics are usually established at the discretion of management, which also decides on continuation or suspension of their funding.

? Among SMEs engaged in R&D, the share of ownership of a developed product or technology is significantly lower than among large firms, which is primarily due to the differences between them in terms of the "use value" of R&D results. If among large manufacturing companies the share of those who have patents for their inventions or the right to practical application of R&D results reaches more than 70%, then among SMEs it is only 12-13%.

The motives behind the desire to obtain one or another type of rights to their inventions are also different for large and small enterprises. If for large companies obtaining rights to inventions is primarily a means of strengthening their positions in the competition, gaining a monopoly position in the market, access to technologies from other firms, and receiving royalties for small businesses, more "moderate" goals are characteristic - gaining the trust of partners, increasing labor motivation of personnel. improving the company's image, etc.

BIBLIOGRAPHY

1. Bok Zi Kou Japan Economy. - M .: Economics, 2002

2. History of Japan. T2, M .: 1998

3. Kostyunina G.M. Asia-Pacific Economic Integration - M .: ROSPENN, 2002

4. Lebedeva The trend of scientific and technical development of small business in Japan / "Problems of theory and practice of management" - 2002 - №3, p. 74-79

5. Leontyeva E. The economic situation of Japan // ME and MO - 2001 - №8, - from 109-1186. Fatkhutdinov R.A. Innovation management. - M .: UNITI, 199816

Japan is known as the country with the most highly developed science. In terms of the number of scientists and engineers (850 thousand), it is second only to the United States and China and shares the third and fourth places with Russia. In terms of the share of R&D expenditures, Japan is also among the top five countries in the world. Using a complex system of coefficients, scientists sometimes calculate the general level of development of science in a particular country. In this case, Japan is at the very beginning of the ranking, ranking third behind Sweden and Switzerland.

From a geographical point of view, the issue of the territorial organization of science in Japan is of greatest interest. This country has always had a very high level of territorial concentration of science, which was almost entirely concentrated in the Kanto, Tokai and Kinki regions. Only in Greater Tokyo more than half of all scientific research carried out in the country was carried out, half of all professors taught in it, more than 40% of all students studied. It is all the more important that in the early 1970s. there was a "great migration" of science from Tokyo to a new city of science - Tsukubu, built specifically for this purpose 60 km northeast of the capital and soon became the country's largest research and development center. This laid the foundation for deconcentration process scientific sphere that in the 1970s. became typical for other spheres of economic and non-economic activity.

In the mid-1990s. already 78 different scientific institutions worked in Tsukuba. Among them are two universities, 46 national research laboratories, 8 private research centers, as well as enterprises and research institutions of private firms. They specialize in higher education (students from 50 countries of the world study in Tsukuba), in research in the field of natural (institutes of geography, environment), technical (metallurgy, synthetic materials) sciences. There is a space center, a library, a science museum, a botanical garden.

But that was only the beginning. A much larger decentralization of research began with the implementation of the Technopolis program. The word "technopolis" ("tekunoporisu") appeared in the Japanese lexicon in 1980. combination of science and industry. In order to better understand this concept itself, it should be remembered that in Japan (as well as in the USA) the overwhelming part of R&D expenditures, exceeding 90%, is directed to applied research and development.

The Technopolis program was first formulated in 1980 in a special document prepared by the Ministry of Foreign Trade and Industry of Japan entitled “A Look into the 80s”. It provided for a balanced, organic combination of high-tech industry, science and a favorable living space. Specifically, it was a question of creating research and production towns (technopolises) in different parts of the country, but outside the largest urban agglomerations, in which there should be conditions for research activities, and for high-tech production, and for training personnel. Some experts believe that this program was based on the concept of "growth poles", which was quite popular at that time.

At the same time, the main placement criteria future technopolises:

- proximity (no more than 30 minutes drive) to the "mother city" with a population of 150-200 thousand people, which would provide public services;

- proximity to the airport, and even better to the international airport or to the station of the high-speed railway;

- the presence of a basic university providing training and research in the field of high technologies;

- a balanced set of industrial zones, research institutes and residential areas;

- improved information network;

- favorable conditions for life, conducive to creative scientific work and thinking;

- planning with the participation of all three stakeholders: business, universities and local authorities.

In 1983, a law on technopolises was adopted and its implementation began. At first, the program provided for the creation of only seven to eight technopolises. But it turned out that 40 out of 47 Japanese prefectures expressed their desire to participate in it. Therefore, in 1983-1984. projects of 14 technopolises were approved, and then their total number was brought to 26.

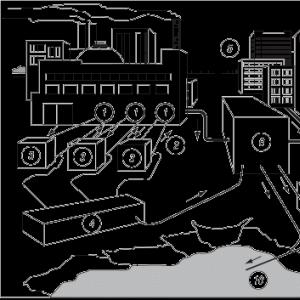

An analysis of the location of these technopolises leads to a number of interesting conclusions. For example, that almost all of them were created outside the Pacific belt. Further, that 12 of them belong (according to V.V.Krysov) to the semi-peripheral, and 14 - to the peripheral regions of Japan. Finally, the fact that technopolises appeared in all economic regions of Japan, but in the greatest number (6 each) in such truly peripheral regions as Tohoku and Kyushu.

The island of Kyushu, formerly known for coal mining and metallurgy, agriculture and fishing, already in the 1970s. gradually became the focus of knowledge-intensive industries - primarily semiconductors, integrated circuits, which is explained by the availability of cheap labor, lower cost of land, and better environmental conditions. Even then, from the mouth of a child, one could hear here: "Grandfather works in the field, father works in the city, and sister works at a high-tech production plant." The Technopolis committee selected the sites here for the creation of six technopolises. It is no coincidence that Kyushu began to be called the Silicon Island.

In accordance with the plan, all technopolises were created at university cities. Many of them (Akita, Utsunomiya, Naga-oka, Hakodate, etc.) and have the same names as their "mother" cities. As for their research profiles, they are very diverse. For example, in Hakodata it is the production of means for the development of the ocean, in Akita - electronics, mecatronics, the production of new materials, in Nagaoka - the production of advanced technical systems, the design industry, in Utsunomiya - electronics, fine chemical technology, in Hamamatsu - optoelectronics, in Toyama - biotechnology. , computer science, in Kumamoto - the production of machines for applied purposes, information systems, etc.

As a result, it can be argued that technopolises in Japan have already become an important link not only in the territorial organization of science, but also in the entire territorial organization of the economy of this country.

78. Japanese technopolises

Japan is known as the country with the most highly developed science. In terms of the number of scientists and engineers (850 thousand), it is second only to the United States and China and shares the third and fourth places with Russia. In terms of the share of R&D expenditures, Japan is also among the top five countries in the world. Using a complex system of coefficients, scientists sometimes calculate the general level of development of science in a particular country. In this case, Japan is at the very beginning of the ranking, ranking third behind Sweden and Switzerland.

From a geographical point of view, of greatest interest is the question of territorial organization of science in Japan. This country has always had a very high level of territorial concentration of science, which was almost entirely concentrated in the Kanto, Tokai and Kinki regions. Only in Greater Tokyo more than half of all scientific research carried out in the country was carried out, half of all professors taught in it, more than 40% of all students studied. It is all the more important that in the early 1970s. there was a "great migration" of science from Tokyo to a new city of science - Tsukubu, built specifically for this purpose 60 km northeast of the capital and soon became the country's largest research and development center. This laid the foundation for deconcentration process scientific sphere that in the 1970s. became typical for other spheres of economic and non-economic activity.

In the mid-1990s. 78 different scientific institutions already worked in Tsukuba. Among them are two universities, 46 national research laboratories, 8 private research centers, as well as enterprises and research institutions of private firms. They specialize in higher education (students from 50 countries of the world study in Tsukuba), in research in the field of natural (institutes of geography, environment), technical (metallurgy, synthetic materials) sciences. There is a space center, a library, a science museum, a botanical garden (Fig. 121).

But that was only the beginning. A much larger decentralization of research began with the implementation of the Technopolis program. The word "technopolis" ("tekunoporisu") appeared in the Japanese lexicon in 1980. combination of science and industry. In order to better understand this concept itself, it should be remembered that in Japan (as well as in the USA) the overwhelming part of R&D expenditures, exceeding 90%, is directed to applied research and development.

Rice. 121. Tsukuba City of Science

The Technopolis program was first formulated in 1980 in a special document prepared by the Ministry of Foreign Trade and Industry of Japan entitled “A Look into the 80s”. It provided for a balanced, organic combination of high-tech industry, science and a favorable living space. Specifically, it was a question of creating research and production towns (technopolises) in different parts of the country, but outside the largest urban agglomerations, in which there should be conditions for research activities, and for high-tech production, and for training personnel. Some experts believe that this program was based on the concept of "growth poles", which was quite popular at that time.

At the same time, the main placement criteria future technopolises:

- proximity (no more than 30 minutes drive) to the "mother city" with a population of 150-200 thousand people, which would provide public services;

- proximity to the airport, and even better to the international airport or to the station of the high-speed railway;

- the presence of a basic university providing training and research in the field of high technologies;

- a balanced set of industrial zones, research institutes and residential areas;

- improved information network;

- favorable conditions for life, conducive to creative scientific work and thinking;

- planning with the participation of all three stakeholders: business, universities and local authorities.

In 1983, a law on technopolises was adopted and its implementation began. At first, the program provided for the creation of only seven to eight technopolises. But it turned out that 40 out of 47 Japanese prefectures expressed their desire to participate in it. Therefore, in 1983-1984. projects of 14 technopolises were approved, and then their total number was brought to 26.

An analysis of the location of these technopolises (Fig. 122) leads to a number of interesting conclusions. For example, that almost all of them were created outside the Pacific belt. Further, that 12 of them belong (according to V.V.Krysov) to the semi-peripheral, and 14 - to the peripheral regions of Japan. Finally, the fact that technopolises appeared in all economic regions of Japan, but in the greatest number (6 each) in such truly peripheral regions as Tohoku and Kyushu.

Rice. 122. Technopolises of Japan (by Sh. Tatsuno)

The island of Kyushu, formerly known for coal mining and metallurgy, agriculture and fishing, already in the 1970s. gradually became the focus of knowledge-intensive industries - primarily semiconductors, integrated circuits, which is explained by the availability of cheap labor, lower cost of land, and better environmental conditions. Even then, from the mouth of a child, one could hear here: "Grandfather works in the field, father works in the city, and sister works at a high-tech production plant." The Technopolis committee selected the sites here for the creation of six technopolises. It is no coincidence that Kyushu began to be called the Silicon Island.

In accordance with the plan, all technopolises were created at university cities. Many of them (Akita, Utsunomiya, Naga-oka, Hakodate, etc.) and have the same names as their "mother" cities. As for their research profiles, they are very diverse. For example, in Hakodata it is the production of means for the development of the ocean, in Akita - electronics, mecatronics, the production of new materials, in Nagaoka - the production of advanced technical systems, the design industry, in Utsunomiya - electronics, fine chemical technology, in Hamamatsu - optoelectronics, in Toyama - biotechnology. , computer science, in Kumamoto - the production of machines for applied purposes, information systems, etc.

Contents Ø What is a technopark Ø Japanese technopolises Ø Influence of technopolises Ø Criteria of technopolises (according to the Japanese version) Ø South Korea Ø Conclusion

Contents Ø What is a technopark Ø Japanese technopolises Ø Influence of technopolises Ø Criteria of technopolises (according to the Japanese version) Ø South Korea Ø Conclusion

What is a technopark? Technopark is a property complex that brings together research institutes, industrial facilities, business centers, exhibition grounds, and educational institutions. Technoparks began in the United States in the early 50s, when the Stanford University Science Park (California) was organized. In Japan, technoparks are called "technopolises". because in many times they exceed the parks both in terms of territory and in terms of the volume of work and research carried out.

What is a technopark? Technopark is a property complex that brings together research institutes, industrial facilities, business centers, exhibition grounds, and educational institutions. Technoparks began in the United States in the early 50s, when the Stanford University Science Park (California) was organized. In Japan, technoparks are called "technopolises". because in many times they exceed the parks both in terms of territory and in terms of the volume of work and research carried out.

Japanese technopolises The Japanese were the first to see in technopolises a model of the future society and put its formation on the rails of state planning. The construction of technopolises is funded not only by the state. Typical sources of funding in Japan: 30% - government funding, 30% - municipalities, 30% - businesses and individuals, 10% - foreign investors.

Japanese technopolises The Japanese were the first to see in technopolises a model of the future society and put its formation on the rails of state planning. The construction of technopolises is funded not only by the state. Typical sources of funding in Japan: 30% - government funding, 30% - municipalities, 30% - businesses and individuals, 10% - foreign investors.

MITI Technopolis Program The MITI Technopolis Program has become one of the key elements of the country's regional development strategy in the context of the transition to a knowledge-based industrial structure. Technopolises are different from the complexes that were created in Japan in the 196070s. Their novelty lies in the fact that the most advanced technologies were chosen as the main lever of economic growth in the peripheral regions.

MITI Technopolis Program The MITI Technopolis Program has become one of the key elements of the country's regional development strategy in the context of the transition to a knowledge-based industrial structure. Technopolises are different from the complexes that were created in Japan in the 196070s. Their novelty lies in the fact that the most advanced technologies were chosen as the main lever of economic growth in the peripheral regions.

Influence of technopolises Technopolises have become strongholds for the development of peripheral regions. At the initiative of the government, 28 technoparks have been created. Japan's technopark structures have increased the country's competitive advantages and provided an innovative and technological breakthrough in the economy. The Japanese model of technoparks is inherent in other countries of Southeast Asia as well.

Influence of technopolises Technopolises have become strongholds for the development of peripheral regions. At the initiative of the government, 28 technoparks have been created. Japan's technopark structures have increased the country's competitive advantages and provided an innovative and technological breakthrough in the economy. The Japanese model of technoparks is inherent in other countries of Southeast Asia as well.

Technopolis criteria: a) be located no further than 30 minutes from their “parent cities” (with a population of at least 200 thousand people) and within 1 day of driving from Tokyo, Nagoya or Osaka; b) occupy an area less than or equal to 500 square miles; c) have a balanced set of modern scientific and industrial complexes, universities and research institutes, combined with convenient areas for living, equipped with cultural and recreational infrastructure; d) be located in picturesque areas and in harmony with local traditions and natural conditions.

Technopolis criteria: a) be located no further than 30 minutes from their “parent cities” (with a population of at least 200 thousand people) and within 1 day of driving from Tokyo, Nagoya or Osaka; b) occupy an area less than or equal to 500 square miles; c) have a balanced set of modern scientific and industrial complexes, universities and research institutes, combined with convenient areas for living, equipped with cultural and recreational infrastructure; d) be located in picturesque areas and in harmony with local traditions and natural conditions.

SOUTH KOREA As new technologies develop, South Korea has strengthened measures to protect intellectual property rights. The government has introduced several new programs aimed at developing cooperation in scientific research with other countries, both private and public R&D sectors. The South Korean government has transferred the concern for industrial development to private hands and, by promoting the development of high-tech industries and research infrastructure, has removed the restrictions imposed by military dictators on trade and attracting foreign investment.

SOUTH KOREA As new technologies develop, South Korea has strengthened measures to protect intellectual property rights. The government has introduced several new programs aimed at developing cooperation in scientific research with other countries, both private and public R&D sectors. The South Korean government has transferred the concern for industrial development to private hands and, by promoting the development of high-tech industries and research infrastructure, has removed the restrictions imposed by military dictators on trade and attracting foreign investment.

Neighboring countries The economic development model of the Republic of Korea is similar to that of Japan. Unlike its northern neighbor, the Republic of Korea has built a high-tech industry in four decades. In 1987, the Ministry of Science and Technology of Korea developed a fifteen-year plan that determined the main directions of the state's scientific and technological policy. It outlined the development of microelectronics and pure chemistry, computer science and production automation.

Neighboring countries The economic development model of the Republic of Korea is similar to that of Japan. Unlike its northern neighbor, the Republic of Korea has built a high-tech industry in four decades. In 1987, the Ministry of Science and Technology of Korea developed a fifteen-year plan that determined the main directions of the state's scientific and technological policy. It outlined the development of microelectronics and pure chemistry, computer science and production automation.

Seoul, Gyeongju, Busan In the 80s of the last century, research and production parks (technoparks), research institutes and risk firms in the field of high technologies began to be created in the country. Thanks to financial and tax incentives, large enterprises from leading industries in Korea and foreign companies took part in them.

Seoul, Gyeongju, Busan In the 80s of the last century, research and production parks (technoparks), research institutes and risk firms in the field of high technologies began to be created in the country. Thanks to financial and tax incentives, large enterprises from leading industries in Korea and foreign companies took part in them.

Conclusion Thus, we can say that technoparks had a significant impact on the development of Japan and South Korea in the 80 -90s of the last century, and despite their small number, they contributed to the emergence of these countries in the leading positions in the field of microelectronics.

Conclusion Thus, we can say that technoparks had a significant impact on the development of Japan and South Korea in the 80 -90s of the last century, and despite their small number, they contributed to the emergence of these countries in the leading positions in the field of microelectronics.

Experience in creating technology parks in the Asia-Pacific region

The practice of the functioning of technological parks (TP) in the countries of the Asia-Pacific region (APR) testifies to the high efficiency of the concentration of scientific, technical, production and financial resources in technoparks and technopolises. Reasonable state innovation policy has a significant impact on the economic growth of countries, contributes to the development of their scientific and technological potential. An important feature is that the state is the main investor in high-tech industries, as well as an active participant in the implementation of innovative projects. The accelerated process of commercialization of scientific achievements confirms the relevance and effectiveness of the selected innovation policy of the APR countries.

Scientific and technical policy in the countries of the region is implemented through mechanisms for allocating budget funds to support high-tech production and industries that produce competitive products based on the latest achievements of science and technology, requiring significant R&D costs and attracting qualified personnel. Undoubtedly, the existence of TP in the countries of the region is impossible without the support of local governments, cooperation between research centers and industrial enterprises, and joint, including international, research and development projects. At the same time, the development of integration ties with neighboring countries of the region, as well as the attraction of direct foreign investments, is considered an important point. As part of this policy, the antimonopoly, licensing, tax and customs regulatory frameworks are being revised. In a number of countries, additional measures are provided for preferential taxation of industries related to the activities of TP, the transfer of intellectual property rights to R&D performers, which were financed from the state budget, is allowed. These measures really contribute to the expansion of interaction between scientific institutions and innovation firms, as well as contribute to the economic growth of the region. Thus, it can be assumed that in the near future there will be a tendency towards the development of technopark zones, cooperation of scientific institutions and industrial firms as one of the promising forms of attracting private capital, commercialization of scientific research, and the development of high-tech industries.

Japan

The leading role in the Asia-Pacific region in terms of research development is played by Japanese technoparks. Functionally, they can be divided into:

Research parks (41 percent of the total), created to introduce the developments of national research institutes into production;

Science parks (33 percent) that promote the creation of new high-tech enterprises;

Innovation centers (26 percent).

About 70 percent of Japanese TPs were created to support small and medium-sized businesses in the regions, while 58 percent of the total is focused on the production of high-tech products. 73 percent of Japanese TSs provide technical support and 52 percent provide other support (in particular, consulting services, marketing research, legal advice) to newly formed firms and enterprises in the region.

For the development of national TPs, the government of the country has developed special programs:

- "Plan for the development of technopolises", which provides for the provision of subsidies, low-interest loans for venture capital business, reduction of payments for the lease of industrial facilities and buildings.

- "Plan for the location of scientific production", which presupposes the territorial concentration of regional industries and their association by specialization.

- A “basic research plan” that promotes the development of an enterprise in the early stages of its existence.

These programs provide for a special role for local self-government bodies, which are empowered to provide additional benefits to project participants, including exemption from local taxes, the allocation of targeted grants and loans from local budgets.

To attract foreign investors, the Japanese government has developed a system of preferential terms. So, for investors intending to invest in research and production facilities in the technology park of Kyushu Island (specializing in the production of microelectronics, communications and computer technologies), the municipal authorities issue loans up to 10 million dollars at 1-8 percent per annum with a maturity up to 10 years (with a 2-year deferral of the first payments).

The Republic of Korea

Of particular interest is the South Korean TP system, which provides for state support for direct ties between large and small enterprises. This stimulates the process of concentration of small firms serving a large enterprise. In addition, the system encourages the participation of parent companies in solving financial issues, in setting up production processes, in staff training.

About 40 percent of Korean firms, which are structurally organized into technoparks, provide technical support, staffing and R&D services jointly with local enterprises located within 30 km. The main tasks solved using the TP system are:

- pooling funds and efforts of universities, public and private companies to conduct research and development in priority areas of the national research program;

- coordination of research of public and private structures, which makes it possible to exclude duplication of R&D on a national scale;

- providing the necessary practical assistance to small and medium-sized businesses operating in knowledge-intensive industries;

- shortening the time interval for introducing the latest developments into production;

- assistance in the formation of venture capital firms created by employees of universities and state research institutes on the basis of the latest technologies proposed by them.

The largest Technopark is "Daeduk" (Daeduk city) located in the south of the country. The Daeduk is the South Korean prototype of the Japanese technopolis in Tsukuba. The main research and development developments of the technopolis are associated with the creation of high-tech goods, new technologies and materials. In addition, fundamental research is also carried out here.

By 2000, it is planned to create six new technoparks in Korea. The government intends to allocate $ 2.97 million annually for the construction and operation of each of them during the first two years.

Thailand

A characteristic feature of the functioning of TP in Thailand was the proximity of high-tech enterprises and industries to Bangkok and other cities where transport and communication infrastructure is most developed. The state promotes the introduction of environmentally friendly, energy efficient advanced technologies, which are key for the development of individual industries. At the moment, the main focus is on the production of products using foreign technologies purchased directly from manufacturers.

The establishment of Thailand's First Science Park is overseen by the National Science and Technology Development Agency under the leadership of the Minister of Science, Technology and Environment. The agency provides support to public and private entrepreneurship in three main national research centers:

Biological;

Metals and Materials;

Electronic and computer technologies.

It also stimulates the conduct of national R&D with the subsequent introduction of the achieved developments into production.

The state provides support to TA by reducing taxes, providing soft loans, grants, helping to find partners and organizing contacts with them, etc.

Indonesia and Malaysia

In Indonesia and Malaysia, there is a strong interest in Russian science-intensive technologies in nuclear energy, biotechnology, optoelectronics, informatics, nanotechnology, alternative energy sources and environmental protection.

At the same time, the policy of states involves the purchase of industrially tested technologies with investment support. A prerequisite is the supply of the necessary modern equipment and the provision of qualified specialists for its operation and maintenance. Often, the technologies and equipment planned for acquisition in Russia form the basis for newly created enterprises within the framework of the TP.

Singapore

In Singapore, the transition to the priority development of knowledge-intensive industries began in the late 1970s. At that moment, the task was set to turn the city-state into a regional center for information and science-intensive industries. Particular attention was paid to the development of biotechnology, electronics, the creation of artificial intelligence, laser technology, robotics, technologies in the field of informatics and communications.

For the effective use of financial resources and coordination of efforts to produce high technology products in the early 80s. A research and production park was established in Singapore. The territory of the technopark is about 30 hectares, where 5 state research institutes are located, including the University of Singapore and about 45 industrial corporations. Technopark is Singapore's largest industrial technology development center and the country's leading innovation center.

In Singapore, companies involved in the development of science and industrial parks are provided with benefits that were given only to firms in export-oriented industries. In particular, such companies are entitled to 100 percent control over a local enterprise, and tax incentives for a fairly long period. Profit tax is halved when investing in research and development. A preferential tax has been introduced for the construction and operation of industrial facilities in the technopark zone.

In the coming years, the Singapore government plans to expand the network of research and production parks, with emphasis on the creation of modern technologies for the production of agricultural products. 10 agrotechnical parks will be formed, where leading experts in the field of zoology, microbiology, genetics, biochemistry, veterinary medicine, entomology, biotechnology, etc. will be concentrated. They will take part in the development of fundamentally new technologies for growing vegetables and fruits, fish farming and the use of seafood. The parks will produce $ 650 million worth of food products, which will meet up to 87 percent of the total needs of Singaporeans for eggs, up to 20 percent for vegetables and fish products, and up to 15 percent for poultry. In the future, the agricultural products of the parks, as well as the developed new technologies for their production, are planned to be exported to the countries of the Asia-Pacific region.

Thus, practice shows that technoparks develop most successfully in those countries where the state supports the development of the scientific and technological revolution and where the task of optimizing the economic system and susceptibility to the achievements of scientific and technological progress is set at the head of this policy.

Scientific and industrial parks are the prototypes of future technopolises - cities of advanced technologies, scientific research and design and development developments. For most developing states and countries with economies in transition, the strategy for the priority development of scientific and industrial parks is a breakthrough into new areas of activity based on the development of a network of regional centers of the highest technological level, intellectualization of the entire national economy. Science, high technologies, traditional national cultures are harmoniously combined in technopolises and a new community of creative and comprehensively developed people is being created.

It is necessary to note another important function of technoparks - the containment of the "brain drain", which is very important for modern Russia, which is turning into a world leader in this area. At present, the majority of Russian young, talented scientists who go abroad to study or on contract remain there for permanent residence, which is due to the destruction of the scientific and technical potential of Russia and the lack of demand for highly qualified scientists and specialists.

The development of a network of technoparks, where favorable conditions for scientific and commercial activities are created, could slow down this process, as well as open up a real opportunity for applying the force of returning scientists who have accumulated experience in leading Western research centers.