How is elasticity measured in physics. Elastic force

Topics of the USE codifier: forces in mechanics, elastic force, Hooke's law.

As we know, on the right side of Newton's second law is the resultant (that is, the vector sum) of all forces applied to the body. Now we have to study the forces of interaction of bodies in mechanics. There are three types: elastic force, gravitational force and friction force. Let's start with elasticity.

Deformation.

Elastic forces arise during deformations of bodies. Deformation is a change in the shape and size of the body. Deformations include tension, compression, torsion, shear and bending.

Deformations are elastic and plastic. Elastic deformation completely disappears after the termination of the action of the external forces causing it, so that the body completely restores its shape and dimensions. Plastic deformation is preserved (perhaps partially) after the removal of the external load, and the body no longer returns to its previous size and shape.

The particles of the body (molecules or atoms) interact with each other by attractive and repulsive forces of electromagnetic origin (these are the forces acting between the nuclei and electrons of neighboring atoms). The forces of interaction depend on the distances between the particles. If there is no deformation, then the forces of attraction are compensated by the forces of repulsion. During deformation, the distances between the particles change, and the balance of interaction forces is disturbed.

For example, when a rod is stretched, the distances between its particles increase, and attractive forces begin to prevail. On the contrary, when the rod is compressed, the distances between the particles decrease, and the repulsive forces begin to predominate. In any case, a force arises that is directed in the direction opposite to the deformation, and tends to restore the original configuration of the body.

Elastic force - this is the force that arises during the elastic deformation of the body and is directed in the direction opposite to the displacement of the particles of the body in the process of deformation. Elastic force:

1. acts between adjacent layers of a deformed body and is applied to each layer;

2. acts from the side of the deformed body on the body in contact with it, causing deformation, and is applied at the point of contact of these bodies perpendicular to their surfaces (a typical example is the support reaction force).

The forces arising from plastic deformations do not belong to the elastic forces. These forces do not depend on the magnitude of the deformation, but on the rate of its occurrence. The study of such forces

goes far beyond the curriculum.

In school physics, tensions of threads and cables, as well as tensions and compressions of springs and rods are considered. In all these cases, the elastic forces are directed along the axes of these bodies.

Hooke's law.

The deformation is called small if the change in body size is much less than its original size. At small deformations, the dependence of the elastic force on the magnitude of the deformation turns out to be linear.

Hooke's Law . The absolute value of the elastic force is directly proportional to the magnitude of the deformation. In particular, for a spring compressed or stretched by an amount , the elastic force is given by the formula:

(1)

where is the spring constant.

The stiffness coefficient depends not only on the material of the spring, but also on its shape and dimensions.

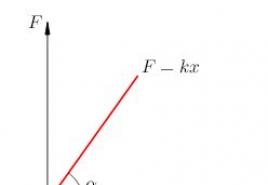

From formula (1) it follows that the graph of the dependence of the elastic force on (small) deformation is a straight line (Fig. 1):

|

| Rice. 1. Hooke's Law |

The stiffness coefficient is about the angular coefficient in the straight line equation. Therefore, the equality is true:

where is the angle of inclination of this straight line to the abscissa axis. This equality is convenient to use when experimentally finding the quantity .

We emphasize once again that Hooke's law on the linear dependence of the elastic force on the magnitude of the deformation is valid only for small deformations of the body. When the deformations cease to be small, this dependence ceases to be linear and acquires a more complex form. Accordingly, the straight line in Fig. 1 is only a small initial part of the curvilinear graph describing the dependence on for all values of strain .

Young's modulus.

In the particular case of small deformations rods there is a more detailed formula that refines the general form ( 1 ) of Hooke's law.

Namely, if the rod length and cross-sectional area stretch or compress

by the value , then the formula is valid for the elastic force:

Here - Young's modulus rod material. This coefficient no longer depends on the geometric dimensions of the rod. Young's moduli of various substances are given in reference tables.

The coefficient E in this formula is called Young's modulus. Young's modulus depends only on the properties of the material and does not depend on the size and shape of the body. For different materials, Young's modulus varies widely. For steel, for example, E ≈ 2 10 11 N / m 2, and for rubber E ≈ 2 10 6 N / m 2, that is, five orders of magnitude less.

Hooke's law can also be generalized to the case of more complex deformations. For example, when bending deformations the elastic force is proportional to the deflection of the rod, the ends of which lie on two supports (Fig. 1.12.2).

|

| Figure 1.12.2. bending deformation. |

The elastic force acting on the body from the side of the support (or suspension) is called support reaction force. When the bodies come into contact, the reaction force of the support is directed perpendicular contact surfaces. Therefore, it is often called strength. normal pressure. If the body lies on a horizontal fixed table, the reaction force of the support is directed vertically upwards and balances the force of gravity: The force with which the body acts on the table is called body weight.

In technology, spiral-shaped springs(Fig. 1.12.3). When springs are stretched or compressed, elastic forces arise, which also obey Hooke's law. The coefficient k is called spring rate. Within the limits of applicability of Hooke's law, springs are capable of greatly changing their length. Therefore, they are often used to measure forces. A spring whose tension is graduated in units of force is called dynamometer. It should be borne in mind that when a spring is stretched or compressed, complex torsion and bending deformations occur in its coils.

|

| Figure 1.12.3. Spring extension deformation. |

Unlike springs and some elastic materials (such as rubber), the tensile or compression deformation of elastic rods (or wires) obeys Hooke's linear law within very narrow limits. For metals, the relative deformation ε = x / l should not exceed 1%. At large deformations, irreversible phenomena (fluidity) and destruction of the material occur.

§ 10. Force of elasticity. Hooke's Law

Types of deformations

deformation called a change in the shape, size or volume of the body. Deformation can be caused by the action of external forces applied to the body.

Deformations that completely disappear after the cessation of the action of external forces on the body are called elastic, and the deformations that persist even after the external forces have ceased to act on the body, - plastic.

Distinguish tensile strain or compression(one-sided or all-sided), bending, torsion and shear.

elastic forces

When a solid body is deformed, its particles (atoms, molecules, ions) located at the nodes of the crystal lattice are displaced from their equilibrium positions. This displacement is counteracted by the forces of interaction between the particles of a solid body, which keep these particles at a certain distance from each other. Therefore, with any type of elastic deformation, internal forces arise in the body that prevent its deformation.

The forces that arise in the body during its elastic deformation and directed against the direction of displacement of the particles of the body caused by deformation are called elastic forces. Elastic forces act in any section of the deformed body, as well as in the place of its contact with the body causing deformation. In the case of unilateral tension or compression, the elastic force is directed along the straight line along which the external force acts, causing the body to deform, opposite to the direction of this force and perpendicular to the surface of the body. The nature of elastic forces is electrical.

We will consider the case of the appearance of elastic forces during unilateral tension and compression of a solid body.

Hooke's Law

The relationship between the elastic force and the elastic deformation of a body (for small deformations) was experimentally established by Newton's contemporary, the English physicist Hooke. The mathematical expression of Hooke's law for the deformation of one-sided tension (compression) has the form

where f is the elastic force; x - elongation (deformation) of the body; k - coefficient of proportionality, depending on the size and material of the body, called stiffness. The SI unit of stiffness is newton per meter (N/m).

Hooke's Law for unilateral tension (compression) formulate as follows: the elastic force that occurs when a body is deformed is proportional to the elongation of this body.

Consider an experiment illustrating Hooke's law. Let the axis of symmetry of the cylindrical spring coincide with the line Ax (Fig. 20, a). One end of the spring is fixed in the support at point A, and the other is free and body M is attached to it. When the spring is not deformed, its free end is at point C. This point will be taken as the origin of the x coordinate, which determines the position of the free end of the spring.

Consider an experiment illustrating Hooke's law. Let the axis of symmetry of the cylindrical spring coincide with the line Ax (Fig. 20, a). One end of the spring is fixed in the support at point A, and the other is free and body M is attached to it. When the spring is not deformed, its free end is at point C. This point will be taken as the origin of the x coordinate, which determines the position of the free end of the spring.

We stretch the spring so that its free end is at point D, the coordinate of which is x>0: At this point, the spring acts on the body M with an elastic force

Let us now compress the spring so that its free end is at point B, the coordinate of which is x<0. В этой точке пружина действует на тело М упругой силой

It can be seen from the figure that the projection of the elastic force of the spring on the axis Ax always has a sign opposite to the sign of the x coordinate, since the elastic force is always directed towards the equilibrium position C. In fig. 20b shows a graph of Hooke's law. On the abscissa axis, the values of the elongation x of the spring are plotted, and on the ordinate axis, the values of the elastic force. The dependence of fx on x is linear, so the graph is a straight line passing through the origin.

Let's consider another experience.

Let's consider another experience.

Let one end of a thin steel wire be fixed on a bracket, and a load is suspended from the other end, the weight of which is the external tensile force F acting on the wire perpendicular to its cross section (Fig. 21).

The action of this force on the wire depends not only on the modulus of force F, but also on the cross-sectional area of the wire S.

Under the action of an external force applied to it, the wire is deformed and stretched. With not too much stretching, this deformation is elastic. In the elastically deformed wire there is an elastic force f y.

According to Newton's third law, the elastic force is equal in absolute value and opposite in direction to the external force acting on the body, i.e.

f yn = -F (2.10)

The state of an elastically deformed body is characterized by the value s, called normal mechanical stress(or, for short, just normal voltage). The normal stress s is equal to the ratio of the elastic modulus to the cross-sectional area of the body:

s \u003d f pack / S (2.11)

Let the initial length of the unstretched wire be L 0 . After applying the force F, the wire stretched and its length became equal to L. The value DL \u003d L-L 0 is called absolute elongation of the wire. the value

called relative elongation of the body. For tensile strain e>0, for compressive strain e<0.

Observations show that for small deformations, the normal stress s is proportional to the relative elongation e:

Formula (2.13) is one of the ways of writing Hooke's law for one-sided tension (compression). In this formula, the elongation is taken modulo, since it can be both positive and negative. The coefficient of proportionality E in Hooke's law is called the modulus of longitudinal elasticity (Young's modulus).

Let us establish the physical meaning of Young's modulus. As can be seen from formula (2.12), e=1 and L=2L 0 with DL=L 0 . From formula (2.13) it follows that in this case s=E. Consequently, Young's modulus is numerically equal to such a normal stress that should have arisen in the body when its length is doubled. (if for such a large deformation Hooke's law was fulfilled). From formula (2.13) it is also seen that in SI Young's modulus is expressed in pascals (1 Pa = 1 N/m2).

Stretch Chart

Using formula (2.13), from the experimental values of the relative elongation e, one can calculate the corresponding values of the normal stress s arising in a deformed body and construct a graph of the dependence of s on e. This chart is called stretch diagram. A similar graph for a metal sample is shown in Fig. 22. In section 0-1, the graph looks like a straight line passing through the origin. This means that up to a certain stress value, the deformation is elastic and Hooke's law is fulfilled, i.e., the normal stress is proportional to the relative elongation. The maximum value of the normal stress s p, at which Hooke's law is still fulfilled, is called limit of proportionality.

With a further increase in the load, the dependence of the stress on the relative elongation becomes non-linear (section 1-2), although the elastic properties of the body are still preserved. The maximum value of s for normal stress, at which no permanent deformation occurs, is called elastic limit. (The elastic limit is only hundredths of a percent higher than the proportional limit.) Increasing the load above the elastic limit (section 2-3) leads to the fact that the deformation becomes permanent.

Then the sample begins to elongate at almost constant stress (plot 3-4 of the graph). This phenomenon is called material flow. Normal stress s t, at which the residual deformation reaches a given value, is called yield strength.

At stresses exceeding the yield strength, the elastic properties of the body are restored to a certain extent, and it again begins to resist deformation (section 4-5 of the graph). The maximum value of the normal stress s pr, above which the sample breaks, is called tensile strength.

Energy of elastically deformed body

Substituting the values s and e from formulas (2.11) and (2.12) into formula (2.13), we obtain

f y /S=E|DL|/L 0 .

whence it follows that the elastic force f yn, which occurs when the body is deformed, is determined by the formula

f yn =ES|DL|/L 0 . (2.14)

Let us define the work A def performed during the deformation of the body, and the potential energy W of the elastically deformed body. According to the law of conservation of energy,

W=A def. (2.15)

As can be seen from formula (2.14), the modulus of the elastic force can change. It increases in proportion to the deformation of the body. Therefore, to calculate the work of deformation, it is necessary to take the average value of the elastic force

Then defined by the formula A def =

A def = ES|DL| 2 /2L0 .

Substituting this expression into formula (2.15), we find the value of the potential energy of an elastically deformed body:

W=ES|DL| 2 /2L0 . (2.17)

For an elastically deformed spring ES/L 0 =k is the stiffness of the spring; x is the extension of the spring. Therefore, formula (2.17) can be written as

W=kx2/2. (2.18)

Formula (2.18) determines the potential energy of an elastically deformed spring.

Questions for self-control:

What is distortion?

What is called elastic deformation? plastic?

Name the types of deformations.

What is resilience? How is it directed? What is the nature of this force?

How is Hooke's law formulated and written for unilateral tension (compression)?

What is hardness? What is the SI unit of hardness?

Draw a diagram and explain an experiment illustrating Hooke's law. Plot this law.

Having made an explanatory drawing, describe the process of stretching a metal wire under load.

What is called normal mechanical stress? What formula expresses the meaning of this concept?

What is absolute elongation? relative elongation? What formulas express the meaning of these concepts?

What is the form of Hooke's law in a record containing normal mechanical stress?

What is Young's modulus? What is its physical meaning? What is the unit of Young's modulus in SI?

Draw and explain a tensile diagram for a metal sample.

What is the limit of proportionality? elasticity? fluidity? strength?

Get the formulas by which the work of deformation and the potential energy of an elastically deformed body are determined.

Deformation (from lat. Deformatio - distortion) - change in the shape and size of the body under the influence of external forces.

Deformities occur because different parts of the body move differently. If all parts of the body moved in the same way, then the body would always retain its original shape and dimensions, i.e. would remain undistorted. Let's look at a few examples.

Types of deformation

Tensile and Compressive Deformations. If a force is applied to a uniform rod fixed at one end F along its axis in the direction away from the rod, then it will undergo deformation sprains. Tensile deformation is experienced by cables, ropes, chains in lifting devices, ties between cars, etc. If a force is applied to a fixed rod along its axis towards the rod, then it will undergo compression. Compression deformation is experienced by pillars, columns, walls, building foundations, etc. When stretched or compressed, the cross-sectional area of the body changes.

Shear deformation. Shear deformation can be clearly demonstrated on a model of a solid body, which is a series of parallel plates interconnected by springs (Fig. 3). Horizontal force F shifts the plates relative to each other without changing the volume of the body. In real solids, the volume also does not change during shear deformation. Rivets and bolts that fasten parts of bridge trusses, beams at supports, etc. are subject to shear deformations. Shear at large angles can lead to destruction of the body - shear. Shearing occurs during the operation of scissors, chisels, chisels, saw teeth, etc.

bending deformation. It is easy to bend a steel or wooden ruler with your hands or some other force. Beams and rods located horizontally, under the influence of gravity or loads, bend - they are subjected to bending deformation. Bending deformation can be reduced to non-uniform tension and compression deformation. Indeed, on the convex side (Fig. 4), the material is subjected to tension, and on the concave side, to compression. Moreover, the closer the considered layer is to the middle layer KN, the smaller the tension and compression become. Layer KN, which is not under tension or compression, is called neutral. Because the layers AB and CD are subject to the greatest tension and compression information, then the greatest elastic forces arise in them (in Figure 4, the elastic forces are shown by arrows). From the outer layer to the neutral one, these forces decrease. The inner layer does not experience noticeable deformations and does not resist external forces, and therefore is superfluous in the design. It is usually removed, replacing the rods with pipes, and the bars with T-beams (Fig. 5). Nature itself, in the process of evolution, endowed man and animals with tubular bones of the limbs and made the stems of cereals tubular, combining material savings with the strength and accuracy of "structures".

Torsional deformation. If a rod, one of the ends of which is fixed (Fig. 6), is acted upon by a pair of forces lying in the plane of the cross section of the rod, then it twists. There is, as they say, torsion deformation.

Each cross section is rotated relative to the other around the axis of the rod by some angle. The distance between sections does not change. Thus, experience shows that in torsion the rod can be represented as a system of rigid circles, centered on a common axis. These circles (more precisely, sections) rotate at different angles depending on their distance from the fixed end. The layers are rotated, but at different angles. However, in this case, adjacent layers rotate relative to each other in the same way along the entire rod. Torsional deformation can be considered as a non-uniform shear. Shear inhomogeneity is expressed in the fact that the shear deformation changes along the rod radius. There is no deformation on the axis, and it is maximum at the periphery. At the end of the rod farthest from the fixed end, the angle of rotation is greatest. It is called the twist angle. Torsion is experienced by the shafts of all machines, screws, screwdrivers, etc.

The main deformations are tensile (compression) and shear deformations. During bending deformation, inhomogeneous tension and compression occur, and during torsion deformation, inhomogeneous shear occurs.

Forces of elasticity.

When a solid body is deformed, its particles (atoms, molecules, ions) located at the nodes of the crystal lattice are displaced from their equilibrium positions. This displacement is counteracted by the forces of interaction between the particles of a solid body, which keep these particles at a certain distance from each other. Therefore, with any type of elastic deformation, internal forces arise in the body that prevent its deformation.

The forces arising in the body during its elastic deformation and directed against the direction of displacement of the particles of the body caused by deformation are called elastic forces.

Elastic forces prevent changes in the size and shape of the body. Elastic forces act in any section of the deformed body, as well as in the place of its contact with the body causing deformation. For example, from the side of an elastically deformed board D on a bar WITH lying on it, the force of elasticity acts F control (Fig. 7).

An important feature of the elastic force is that it is directed perpendicular to the contact surface of the bodies, and if we are talking about such bodies as deformed springs, compressed or stretched rods, cords, threads, then the elastic force is directed along their axes. In the case of unilateral tension or compression, the elastic force is directed along the straight line along which the external force acts, causing the body to deform, opposite to the direction of this force and perpendicular to the surface of the body.

The force acting on the body from the side of the support or suspension is called support reaction force or suspension tension force . Figure 8 shows examples of the application of support reaction forces to bodies (forces N 1 , N 2 , N 3 , N 4 and N 5) and suspension tension forces (forces T 1 , T 2 , T 3 and T 4).

Absolute and relative elongation

Linear deformation(tensile strain) is a strain in which only one linear dimension of the body changes.

It is quantified absolute Δ l and relative ε elongation.

\(~\Delta l = |l - l_0|\) ,

where ∆ l– absolute elongation (m); l and l 0 – final and initial body length (m).

- If the body is stretched, then l > l 0 and ∆ l = l – l 0 ;

- if the body is compressed, then l < l 0 and ∆ l = –(l – l 0) = l 0 – l(Fig. 9).

\(~\varepsilon = \frac(\Delta l)(l_0)\) or \(~\varepsilon = \frac(\Delta l)(l_0) \cdot 100%\) ,

where ε – relative elongation of the body (%); Δ l– absolute elongation of the body (m); l 0 – initial body length (m).

Hooke's Law

The relationship between the elastic force and the elastic deformation of a body (for small deformations) was experimentally established by Newton's contemporary, the English physicist Hooke. The mathematical expression of Hooke's law for the deformation of one-sided tension (compression) has the form

\(~F_(ynp) = k \cdot \Delta l\) , (1)

where F upr - the modulus of the elastic force that occurs in the body during deformation (N); Δ l is the absolute elongation of the body (m).

Coefficient k called body stiffness is the coefficient of proportionality between the deforming force and the deformation in Hooke's law.

Spring rate is numerically equal to the force that must be applied to an elastically deformable sample in order to cause its unit deformation.

In the SI system, stiffness is measured in newtons per meter (N/m):

\(~[k] = \frac()([\Delta l])\) .

The stiffness coefficient depends on the shape and dimensions of the body, as well as on the material.

Hooke's Law for unilateral tension (compression) formulate as follows:

the elastic force that occurs when a body is deformed is proportional to the elongation of this body.

mechanical stress.

The state of an elastically deformed body is characterized by the quantity σ called mechanical stress.

Mechanical stress σ equal to the ratio of the elastic modulus F ex to the cross-sectional area of the body S:

\(~\sigma = \frac(F_(ynp))(S)\) .

The mechanical stress is measured in Pa: [ σ ] \u003d N / m 2 \u003d Pa.

Observations show that at small deformations, the mechanical stress σ is proportional to the relative elongation ε:

\(~\sigma = E \cdot |\varepsilon|\) . (2)

This formula is one of the types of writing Hooke's law for one-sided stretching (compression). In this formula, the elongation is taken modulo, since it can be both positive and negative.

Proportionality factor E in Hooke's law is called modulus of elasticity (Young's modulus). It has been experimentally established that

Young's modulus is numerically equal to such a mechanical stress that should have arisen in the body with an increase in its length by 2 times.

Let's prove it: From Hooke's law we get that \(~E = \frac(\sigma)(\varepsilon)\) . If Young's modulus E numerically equal to mechanical stress σ , then \(~\varepsilon = \frac(\Delta l)(l_0) = 1\) . Then \(~\Delta l = l - l_0 = l_0 ; l = 2 l_0\) .

Young's modulus is measured in Pa: [ E] = Pa/1 = Pa.

Practically any body (except rubber) under elastic deformation cannot double its length: it will break much earlier. The greater the modulus of elasticity E, the less the rod is deformed, all other things being equal ( l 0 , S, F). In this way, Young's modulus characterizes the resistance of a material to elastic deformation in tension or compression.

Hooke's law, written in the form (2), can easily be reduced to the form (1). Indeed, substituting into (2) \(~\sigma = \frac(F_(ynp))(S)\) and \(~\varepsilon = \frac(\Delta l)(l_0)\) , we get:

\(~\frac(F_(ynp))(S) = E \cdot \frac(\Delta l)(l_0)\) or \(~F_(ynp) = \frac(E \cdot S)(l_0) \cdot \Delta l\) ,

where \(~\frac(E \cdot S)(l_0) = k\) .

Stretch Chart

To study the tensile strain, a rod made of the material under study is subjected to tension using special devices (for example, using a hydraulic press), and the elongation of the sample and the stress arising in it are measured. According to the results of the experiments, a graph of the dependence of the voltage is drawn σ from elongation ε . This graph is called a stretch diagram (Fig. 10).

Numerous experiments show that at small strains, the stress σ directly proportional to elongation ε (plot OA diagrams) - Hooke's law is satisfied.

The experiment shows that small deformations completely disappear after the load is removed (an elastic deformation is observed). For small deformations, Hooke's law is satisfied. The maximum voltage at which Hooke's law still holds is called limit of proportionalityσ p. It corresponds to the point A diagrams.

If you continue to increase the tensile load and exceed the proportional limit, then the deformation becomes non-linear (line ABCDEK). Nevertheless, with small non-linear deformations, after the load is removed, the shape and dimensions of the body are practically restored (section AB graphics). The maximum stress at which there are no noticeable residual deformations is called elastic limitσ pack. It corresponds to the point V diagrams. The elastic limit exceeds the proportional limit by no more than 0.33%. In most cases, they can be considered equal.

If the external load is such that stresses appear in the body that exceed the elastic limit, then the nature of the deformation changes (section BCDEK). After the load is removed, the sample does not return to its previous dimensions, but remains deformed, although with a lower elongation than under load (plastic deformation).

Beyond the elastic limit at a certain stress value corresponding to the point WITH diagrams, the elongation increases almost without increasing the load (section CD diagrams are almost horizontal). This phenomenon is called material flow.

With a further increase in load, the voltage increases (from the point D), after which a narrowing (“neck”) appears in the least durable part of the sample. Due to the decrease in the cross-sectional area (point E) for further elongation, less stress is needed, but, in the end, the destruction of the sample occurs (point TO). The maximum stress that a sample can withstand without breaking is called tensile strength . Let's denote it σ pch (it corresponds to the point E diagrams). Its value is highly dependent on the nature of the material and its processing.

In order to minimize the possibility of structural failure, the engineer must, when calculating, allow such stresses in its elements that will be only a part of the tensile strength of the material. They are called allowable stresses. The number showing how many times the tensile strength is greater than the allowable stress is called safety factor. Denoting the margin of safety through n, we get:

\(~n = \frac(\sigma_(np))(\sigma)\) .

The margin of safety is chosen depending on many reasons: the quality of the material, the nature of the load (static or changing over time), the degree of danger arising from destruction, etc. In practice, the margin of safety ranges from 1.7 to 10. By choosing the correct margin of safety, the engineer can determine the allowable stress in the structure.

Plasticity and brittleness

A body made of any material with small deformations behaves as elastic. At the same time, almost all bodies can experience plastic deformations to some extent. There are fragile bodies.

The mechanical properties of materials are varied. Materials such as rubber or steel exhibit elastic properties up to relatively large stresses and strains. For steel, for example, Hooke's law holds up to ε = 1%, and for rubber - up to much higher ε , on the order of tens of percent. Therefore, these materials are called elastic.

In wet clay, plasticine or lead, the elastic deformation area is small. Materials in which slight loads cause plastic deformation are called plastic.

The division of materials into elastic and plastic is largely conditional. Depending on the stresses that arise, the same material will behave either as elastic or as plastic. So, at very high stresses, steel exhibits ductile properties. This is widely used in the stamping of steel products using presses that create a huge load.

Cold steel or iron is difficult to forge with a hammer. But after strong heating, it is easy to give them any shape by forging. Plastic at room temperature, lead acquires pronounced elastic properties if it is cooled to a temperature below -100 °C.

Of great importance in practice is the property of solids, called fragility. The body is called fragile, if it collapses under small deformations. Glass and porcelain products are fragile: they break into pieces when dropped to the floor, even from a small height. Cast iron, marble, amber also have increased fragility. On the contrary, steel, copper, lead are not brittle.

The distinctive features of fragile bodies are most easily understood using the dependence σ from ε when stretched. Figure 11, a, b shows the tensile diagrams of cast iron and steel. They show that when cast iron is stretched by only 0.1%, a stress of about 80 MPa arises in it, while in steel it is only 20 MPa with the same deformation.

Rice. eleven

Rice. eleven Cast iron is destroyed immediately at an elongation of 0.45%, almost without experiencing preliminary plastic deformations. Its tensile strength is 1.2∙108 Pa. At steel at ε = 0.45% the deformation is still elastic and failure occurs at ε ≈ 15%. The tensile strength of steel is 700 MPa.

In all brittle materials, the stress increases very rapidly with elongation, and they fail at very small deformations. The plastic properties of brittle materials practically do not manifest themselves.

Literature

- Kabardin O.F. Physics: Ref. materials: Proc. allowance for students. - M.: Enlightenment, 1991. - 367 p.

- Kikoin I.K., Kikoin A.K. Physics: Proc. for 9 cells. avg. school - M .: Pro-sveshchenie, 1992. - 191 p.

- Physics: Mechanics. Grade 10: Proc. for in-depth study of physics / M.M. Balashov, A.I. Gomonova, A.B. Dolitsky and others; Ed. G.Ya. Myakishev. – M.: Bustard, 2002. – 496 p.

- Elementary textbook of physics: Proc. allowance. In 3 volumes / Ed. G.S. Landsberg: v. 1. Mechanics. Heat. Molecular physics. - M.: Fiz-matlit, 2004. - 608 p.

- Yavorsky B.M., Seleznev Yu.A. A reference guide to physics for applicants to universities and self-education. – M.: Nauka, 1983. – 383 p.

Compilers

Vankovich E. (11 "A" MGOL No. 1), Shkrabov A. (11 "B" MGOL No. 1).

We continue the review of some topics from the "Mechanics" section. Our today's meeting is devoted to the force of elasticity.

It is this force that underlies the operation of mechanical watches, towing ropes and cables of cranes, shock absorbers of cars and trains are exposed to it. It is tested by a ball and a tennis ball, a racket and other sports equipment. How does this force arise, and what laws does it obey?

How is the force of elasticity born?

A meteorite under the influence of gravity falls to the ground and ... freezes. Why? Does the earth's gravity disappear? No. Power cannot just disappear. At the moment of contact with the ground balanced by another force equal to it in magnitude and opposite in direction. And the meteorite, like other bodies on the surface of the earth, remains at rest.

This balancing force is the elastic force.

The same elastic forces appear in the body for all types of deformation:

- stretching;

- compression;

- shear;

- bending;

- torsion.

Forces resulting from deformation are called elastic.

The nature of the elastic force

The mechanism of the emergence of elastic forces was explained only in the 20th century, when the nature of the forces of intermolecular interaction was established. Physicists have called them "giant with short arms." What is the meaning of this witty comparison?

Forces of attraction and repulsion act between molecules and atoms of matter. Such an interaction is due to the smallest particles that are part of them, carrying positive and negative charges. These powers are big enough.(hence the word giant), but appear only at very short distances.(with short arms). At distances equal to three times the diameter of the molecule, these particles are attracted, "joyfully" rushing towards each other.

But, having touched, they begin to actively repel each other.

With tensile deformation, the distance between molecules increases. Intermolecular forces tend to shorten it. When compressed, the molecules approach each other, which causes the molecules to repulse.

And, since all types of deformations can be reduced to compression and tension, the appearance of elastic forces for any deformations can be explained by these considerations.

Hooke's Law

A compatriot and contemporary studied the forces of elasticity and their relationship with other physical quantities. He is considered the founder of experimental physics.

Scientist continued his experiments for about 20 years. He conducted experiments on the deformation of the tension of springs by hanging various loads from them. The suspended load caused the spring to stretch until the elastic force that arose in it balanced the weight of the load.

As a result of numerous experiments, the scientist concludes: the applied external force causes the appearance of an elastic force equal to it in magnitude, acting in the opposite direction.

The law formulated by him (Hooke's law) is as follows:

The elastic force arising from the deformation of the body is directly proportional to the magnitude of the deformation and is directed in the direction opposite to the movement of particles.

The formula for Hooke's law is:

- F is the modulus, i.e. the numerical value of the elastic force;

- x - change in body length;

- k - coefficient of rigidity, depending on the shape, size and material of the body.

The minus sign indicates that the elastic force is directed in the direction opposite to the particle displacement.

Each physical law has its limits of application. The law established by Hooke can only be applied to elastic deformations, when, after the load is removed, the shape and dimensions of the body are completely restored.

In plastic bodies (plasticine, wet clay) such restoration does not occur.

All solids have elasticity to some degree. The first place in elasticity is occupied by rubber, the second -. Even very elastic materials under certain loads can exhibit plastic properties. This is used for the manufacture of wire, cutting out parts of complex shape with special stamps.

If you have a hand-held kitchen scale (steelyard), then the maximum weight for which they are designed is probably written on them. Let's say 2 kg. When hanging a heavier load, the steel spring inside them will never recover its shape.

The work of the elastic force

Like any force, the force of elasticity, able to do the job. And very useful. She protects the deformable body from destruction. If she does not cope with this, the destruction of the body occurs. For example, a crane cable breaks, a string on a guitar, an elastic band on a slingshot, a spring on a scale. This work always has a minus sign, since the elastic force itself is also negative.

Instead of an afterword

Armed with some information about elastic forces and deformations, we can easily answer some questions. For example, why do large human bones have a tubular structure?

Bend a metal or wooden ruler. Its convex part will experience tensile deformation, and the concave part will experience compression. The middle part of the load does not carry. Nature took advantage of this circumstance, supplying man and animals with tubular bones. In the process of movement, bones, muscles and tendons experience all kinds of deformations. The tubular structure of the bones greatly facilitates their weight, without affecting their strength at all.

The stems of cereal crops have the same structure. Gusts of wind bend them to the ground, and elastic forces help to straighten up. By the way, the bicycle frame is also made of tubes, not rods: the weight is much less and the metal is saved.

The law established by Robert Hooke served as the basis for the creation of the theory of elasticity. Calculations performed according to the formulas of this theory allow ensure the durability of high-rise structures and other structures.

If this message was useful to you, I would be glad to see you

If a load is placed on the middle of a board lying horizontally on two supports, then under the action of gravity for some time the load will move down, bending the board, and then stop.

This stop can be explained by the fact that in addition to the force of gravity directed downwards, another force directed upwards acted on the board. When moving down, the board is deformed, and a force arises with which the support acts on the body lying on it, this force is directed upward, that is, in the direction opposite to gravity. This force is called elastic force. When the elastic force becomes equal to the force of gravity acting on the body, the support and the body stop.

The elastic force is the force that arises when the body is deformed (that is, when its shape and size change) and is always directed in the direction opposite to the deforming force.

The cause of the elastic force

Cause emergence of elastic forces is the interaction of body molecules. Molecules repel at short distances, and attract at large distances. Of course we are talking about distances comparable to the size of the molecules themselves.

In an undeformed body, the molecules are at such a distance at which the forces of attraction and repulsion are balanced. When the body is deformed (under tension or compression), the distances between the molecules change - either the forces of attraction or repulsion begin to predominate. As a result, there is elastic force, which is always directed so as to reduce the amount of deformation of the body.

Hooke's Law

If one weight is hung to the spring, then we will see that the spring has deformed - it has lengthened by a certain amount X . If two identical weights are suspended from the spring, we will see that the elongation has become twice as large. The elongation of the spring is proportional to the force of elasticity.

The elastic force arising from the deformation of the body is proportional to the elongation of the body in absolute value and is directed in such a way that it tends to reduce the amount of deformation of the body.

Hooke's law is valid only for elastic deformations, that is, such types of deformation that disappear when the deforming force ceases to act!!!

Hooke's law can be written as a formula:

where k is the stiffness of the spring;

X- elongation of the spring (equal to the difference between the final and initial length of the spring);

the “–” sign shows that the elastic force is always directed in the opposite direction of the deforming force.

"Varieties" of the elastic force

The elastic force acting on the side of the support is called force of normal support reaction . Normal from the word "normal", that is, the reaction of the support is always perpendicular surfaces.

The elastic force acting on the side of the suspension is called thread tension (suspension) .